Table of Contents

ToggleOne Spec, Two Very Different Quotes

Jessica, a sourcing manager for an agricultural-robotics start-up, issued an RFQ for “motor-control cable.” Two suppliers replied. One quoted a wire harness for US $7.30; another proposed a cable assembly for US $11.80. Both claimed to meet IPC/WHMA-A-620E. Why the 62 % gap? To avoid Jessica’s dilemma—and the costly redesign that followed—you need to grasp the terminology before you put anything out to bid.

1 | Definitions—Peeling Back the Jacket

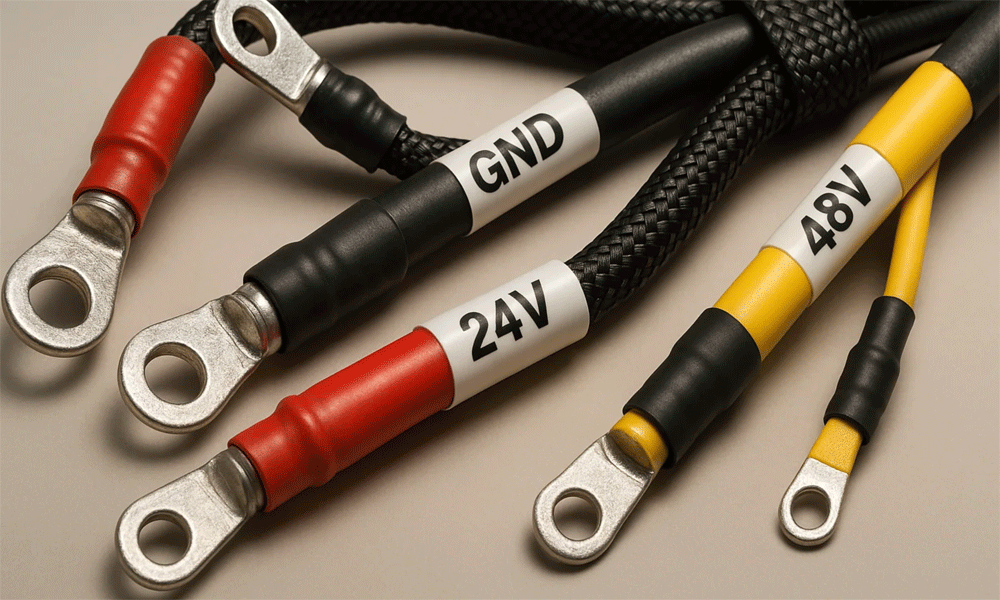

Industry literature and standards bodies draw the line at how the conductors are organised and protected. A wire harness is a bundle of individually sleeved—or sometimes entirely exposed—conductors tied together with lacing, tubing, or loom tape. The bundle offers routing convenience but little added environmental defence. A cable assembly, by contrast, starts with multiple insulated conductors that are stranded or braided, packed with fillers, and finally extruded in one continuous outer jacket that serves as the primary barrier against abrasion, moisture, and EMI.

The IPC/WHMA-A-620E standard treats both under one umbrella but repeatedly distinguishes “harness” from “cable assembly” when specifying workmanship and test criteria.

2 | Functional Architecture—Branching vs Point-to-Point

Think of a wire harness as a rail-yard track: multiple “lines” diverge toward different terminations, often over short distances inside an enclosure. A cable assembly, on the other hand, behaves like an express tunnel: one jacketed cord carries all circuits along the same path to a single mating point.

Because harness break-outs can be staggered anywhere along the route, they excel at complex in-cabinet routing (e.g., servo drives). Cable assemblies shine in point-to-point interconnects such as robot arm power links or medical-device umbilicals, where flex life and ingress protection outrank modular branching.

3 | Cost & Life-Cycle Economics—Why the Price Diverges

Materials: A full PVC, PUR, or TPE jacket in a cable assembly can account for 20–30 % of its raw-material cost—absent in most wire harnesses.

Labour: Harnesses require more hand-termination and lacing; assemblies leverage automated cut-strip-crimp and over-mould presses.

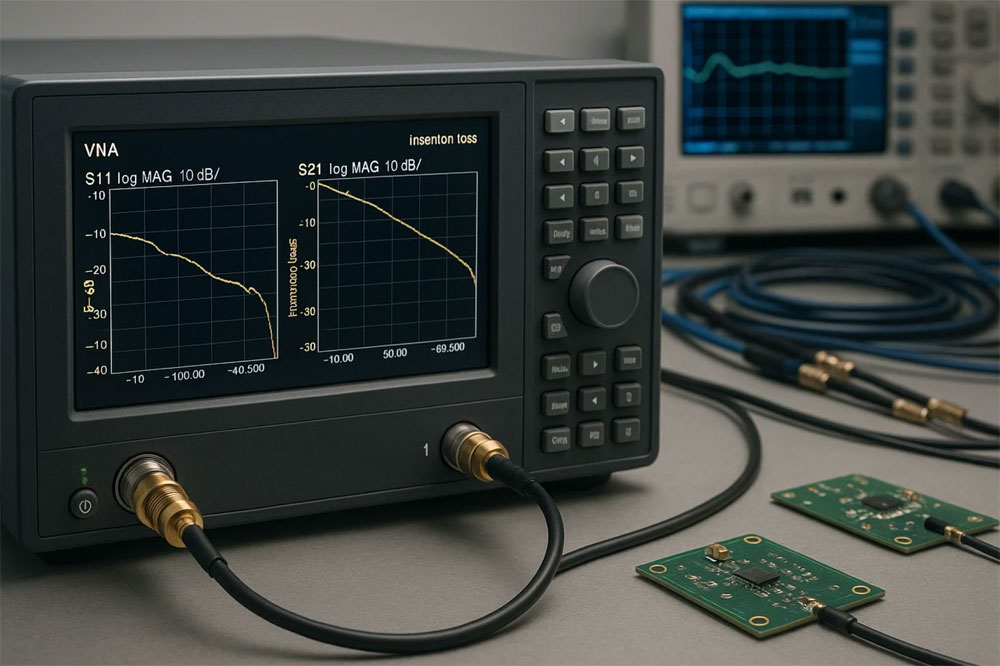

Testing: Continuity checks suffice for many harnesses, whereas assemblies destined for dynamic or outdoor use need HiPot, flex, and ingress tests, inflating NRE fees.

Failure Impact: When a harness conductor chafes, you replace a branch; when a cable assembly jacket fails, the entire link is scrap—a hidden end-of-life cost.

Total-cost models show that for humid, mobile, or chemically harsh installations, the extra $4 cable premium is repaid within 18 months in reduced downtime.

4 | Protection & Compliance—Layers That Matter

UL marking rules illustrate the protection delta: a cable assembly earns a single UL file for the finished product; harnesses rely on each individual wire’s UL recognition and must document that chain during inspection.

From a buyer’s risk perspective:

| Risk Factor | Wire Harness | Cable Assembly |

|---|---|---|

| Abrasion & Cut-Through | Low-to-Moderate | High Resistance |

| UV / Oil / Chemical | Needs extra sleeving | Jacket rated per UL/CSA |

| EMI Shielding | Add braid/foil per branch | Integral 360° braid |

| IP Rating | Rarely beyond IP20 | IP65–IP68 common |

If your product claims IP54 or higher, a cable assembly is nearly always the safer audit path.

5 | Design & Standardisation—Working With IPC/WHMA-A-620E

Revision E (2022) tightened pull-force tables and introduced Class 3 “Space & Critical” criteria for both harnesses and assemblies. Yet manufacturers confirm that meeting Class 3 on a harness is usually less expensive, because conductors are exposed for easier inspection. On a sealed cable assembly, non-destructive inspection tools (X-ray, CT) may be required to verify crimp height or solder-cup fill, adding both capex and lead time.

Take-away: Specify the performance class first; let the CM propose whether a harness or a cable assembly is the most economical route to compliance.

6 | Procurement Checklist—Choosing the Right Construction

Before issuing your RFQ, answer these five questions:

Environment: Will the link see flex, UV, solvents, or splash?

Circuit Complexity: Do you need mid-span branch-outs?

Ingress Target: Any IP rating ≥ IP54 points toward an assembly.

Regulatory Path: UL Field Label or full UL Listed? CE low-voltage?

Service Strategy: Can maintenance teams repair individual conductors on-site?

Suppliers can then bid apples to apples, sparing you Jessica’s surprise.

7 | Application Snapshot—Agritech Drone vs Factory Robot

Agritech Spraying Drone: Lines exit a sealed battery bay, loop through articulated arms, and endure fertiliser mist. An over-moulded PUR cable assembly with braided shield, IP67 connectors, and flex-rated conductors survived 500 000 bend cycles and cut downtime by 23 %.

Six-Axis Welding Robot Controller: Inside a IP20 cabinet, twenty low-voltage signal leads split to I/O boards only 400 mm apart. A colour-coded wire harness with modular headers reduced BOM by 18 % and shaved 1.2 kg versus an equivalent multicore cable.

The lesson: environment and routing anatomy trump preconceived labels.

Conclusion – Terminology as a Strategic Lever

Understanding the nuanced divide between wire harnesses and cable assemblies is more than vocabulary; it is a cost-avoidance and reliability strategy. Harnesses favour short, complex, protected spaces; cable assemblies dominate long-run, harsh-environment, high-flex roles. Specify the operating conditions, compliance targets, and maintenance philosophy first—then let construction follow.

Need help translating specs into the right build? Talk with Infinite Possibilities Technology. Our engineers design both harnesses and cable assemblies, starting at pilot lots of 50 pcs and scaling to 50 k+, all to IPC/WHMA-A-620E Class 2 or 3.