Testing & Inspections

Testing & Inspections

At Infinite Possibilities, we understand that the reliability of a wiring harness depends on more than just high-quality materials—it requires rigorous testing and inspections at every stage of production. Our comprehensive quality control process ensures that each wiring solution meets the highest standards of durability, electrical performance, and safety before reaching our customers.

We adhere to internationally recognized industry standards, including ISO 9001, IATF 16949, and UL, ensuring compliance with the strictest regulations. Whether for automotive, industrial, medical, or consumer electronics applications, our testing protocols are designed to identify potential issues early, enhance product longevity, and provide our clients with consistent, defect-free wiring solutions.

Key Tests & Inspections

At Infinite Possibilities, every wiring harness undergoes a series of rigorous tests and inspections to ensure optimal performance, durability, and compliance with industry standards.

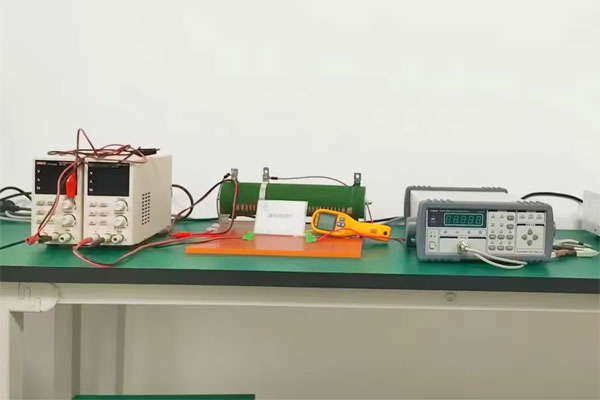

Electrical Testing

We verify the continuity, insulation resistance, and current-carrying capacity of each wiring harness to ensure stable electrical performance and prevent failures in real-world applications.

Tensile Strength Test

Our pull-force testing ensures that terminals and connectors can withstand mechanical stress, guaranteeing secure and reliable connections under various operating conditions.

Continuity & Short Testing

We conduct automated continuity and short circuit tests to detect any electrical faults, ensuring that each harness functions correctly and safely upon installation.

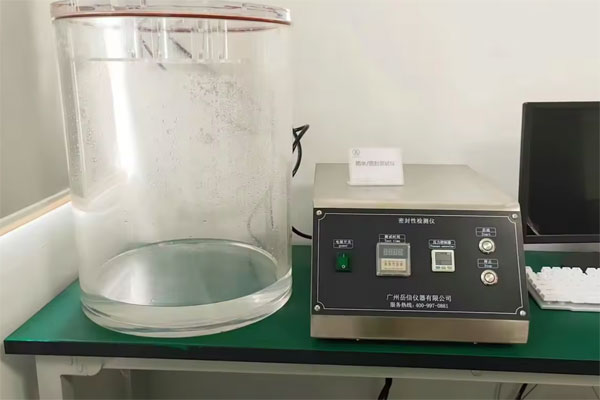

Environmental Testing

Simulating extreme conditions such as temperature fluctuations, humidity, vibration, and chemical exposure, we assess the harness's resilience and long-term reliability in challenging environments.

Durability & Flexibility Testing

Through repeated bending and flexing cycles, we ensure that the wiring harness can endure continuous movement and mechanical stress without compromising its structural integrity.

Visual & Dimensional Inspection

Each harness undergoes a meticulous inspection to verify dimensions, assembly precision, and surface quality, ensuring compliance with customer specifications and zero-defect delivery.

Compliance & Certification

At Infinite Possibilities, we prioritize quality, safety, and regulatory compliance to ensure that every wiring harness meets or exceeds industry standards. Our strict adherence to globally recognized certifications reinforces our commitment to delivering reliable and high-performance solutions.

We are certified under ISO 9001, IATF 16949, CE,Rohs,FCC and UL, ensuring our products comply with stringent automotive, industrial, and electronic safety requirements. Additionally, we provide detailed testing reports, compliance documentation, and third-party inspection certificates upon request, giving our customers full transparency and confidence in the quality of our wiring solutions.

If you have any specific certification requirements, please email me, and I will send the relevant documents to you as soon as possible.

How We Support Our Clients

At Infinite Possibilities, we go beyond standard testing—we provide customized inspection and testing solutions tailored to your specific needs. Whether you require additional performance testing, regulatory compliance verification, or specialized inspections, our team is equipped to deliver precise and reliable results.

Our rigorous testing processes help reduce product failure risks, enhance reliability, and ensure seamless integration into your final application. By continuously optimizing our quality control methods, we empower our clients with high-performance wiring solutions that meet the most demanding industry standards.