Renewable Energy

Reliable Wiring for Solar, Wind & Storage Systems

Clean Energy Needs Clean, Reliable Wiring — and That’s Where We Come In

- In solar, wind, and battery storage systems, even a small wiring issue can lead to energy losses, overheating, or expensive downtime. Harsh outdoor conditions—like UV exposure, rain, sand, and extreme temperatures—only make things worse. For EPC contractors and system integrators, wiring is often the weakest link in an otherwise powerful system.

- At Infinite, we specialize in designing and manufacturing custom wire harnesses and cable assemblies that are built for the demands of renewable energy. From high-voltage DC links to weather-sealed signal harnesses, our products are engineered to perform in the toughest environments. We use only certified materials, implement strict quality control, and offer full traceability to support global compliance needs.

- The result? Faster installation, fewer field failures, and higher long-term efficiency for your systems. Whether you’re building solar farms, wind power stations, or next-gen energy storage units, our wiring solutions help you deliver more power, more reliably—with less risk and rework.

Get a Free Quote Now

Smart Wiring Solutions

Tailored harness designs that solve real problems in compact, connected electronics.

Harsh Outdoor Environments

Challenge: Solar and wind systems often operate under intense sun, rain, snow, dust, and temperature fluctuations.

Solution: We use UV-resistant, high-temperature, and flame-retardant materials with IP-rated connectors to ensure long-term reliability in outdoor installations.

Downtime from Wiring Failures

Challenge: A single faulty cable or connection can lead to system shutdown, reduced output, and costly delays.

Solution: All harnesses undergo 100% electrical testing, with quality traceability and redundant design options to minimize field failures.

Complexity in System Integration

Challenge: Large-scale renewable projects require precise coordination between modules, inverters, storage, and grid interfaces.

Solution: We provide labeled, modular harness kits tailored to your system layout, reducing onsite wiring errors and installation time.

Energy Efficiency Losses

Challenge: Poor contact, voltage drop, or signal noise can reduce energy output and trigger safety risks.

Solution: Our harnesses are engineered for low-resistance, high-conductivity performance with proper shielding and termination.

Sourcing Compatibility & Compliance

Challenge: Many projects require components that meet international certifications (UL, TUV, RoHS, REACH) to ensure safety and approval.

Solution: We work only with certified materials and offer compliance-ready documentation to meet global market entry standards.

Scalability for Growing Project Demands

Challenge: As renewable projects expand, maintaining consistent wiring quality across hundreds or thousands of units becomes harder.

Solution: Our streamlined production lines and flexible batch sizes ensure consistent harness quality from pilot phase to full-scale deployment.

Typical Applications

From smart homes to wearable tech, we deliver precision wiring that powers modern life.

Solar PV Array Connections

Custom harnesses designed for connecting photovoltaic panels in series or parallel, built to handle outdoor exposure and ensure low-loss DC transmission.

Inverter & Combiner Box Wiring

High-current wiring between combiner boxes and inverters, enabling efficient power flow with safe connections and thermal reliability.

Wind Turbine Wiring

Flexible, vibration-resistant harnesses for nacelles and towers, supporting pitch systems, sensors, and rotating equipment.

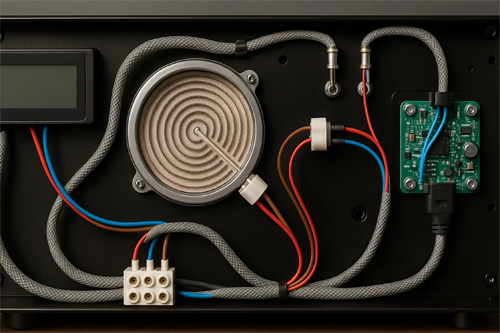

Energy Storage System Wiring

Shielded and flame-retardant cables for battery modules, BMS, and inverters, built to support high-current and safe operation.

EV Charging Station Cabling

Durable assemblies for AC/DC chargers, featuring waterproof protection and compliance with charging standards.

Microgrid & Off-Grid Cabling

Modular harnesses for hybrid energy systems in remote areas, supporting easy installation and long-term reliability.

Wiring the Future of Renewable Energy

Custom-engineered harnesses for solar, wind, and energy storage systems—built to perform in the world’s toughest environments.

Recommended Products

Engineered for Solar and Wind Power Systems

PV Harness with MC4 Connectors

UV-resistant and weatherproof harnesses with MC4-compatible connectors, ideal for connecting photovoltaic modules in rooftop and utility-scale solar arrays.

Low-resistance, flame-retardant DC cables designed to connect solar panels, combiner boxes, and inverters with efficient power transmission.

Flexible, shielded signal harnesses for pitch control, sensor feedback, and nacelle monitoring in wind turbines.

High-durability power cables for vertical tower runs, built to withstand vibration, moisture, and temperature variation.

What You Gain

Real-World Benefits That Power Your Renewable Energy Projects

Faster Onsite Installation

Modular harness kits reduce wiring complexity in solar farms and energy storage containers, cutting down installation time and labor costs.

Reliability in Harsh Conditions

UV-resistant, waterproof, and vibration-proof harnesses built for extreme heat, cold, and moisture in outdoor wind and solar environments.

Better Transmission Performance

Low-resistance, high-conductivity wiring minimizes power loss in long-distance PV strings, wind turbines, and battery connections.

Safer System Operation

All harnesses meet UL, TUV, and IEC standards for flame retardancy, insulation, and voltage endurance, reducing system-level safety risks.

Flexible for Distributed & Modular

Tailored harnesses adapt to rooftop PVs, microgrids, or containerized BESS setups with varying sizes and layouts.

Fast Scaling & Global Expansion

Scalable supply and compliance-ready products help integrators and OEMs roll out renewable systems across different countries and climates.

Easier Maintenance and Troubleshooting

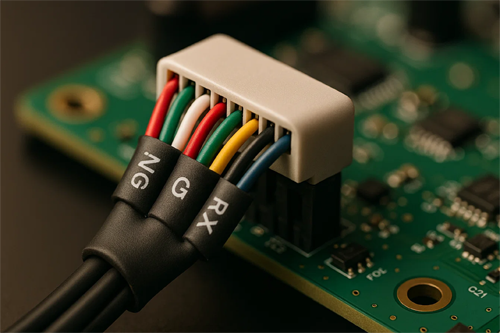

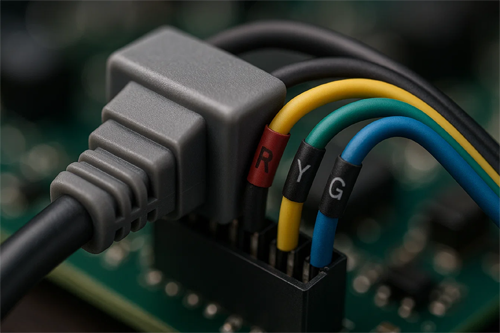

Each harness can be labeled, color-coded, or serialized for faster identification and replacement in field service operations.

Seamless Integration

Custom-tailored wiring interfaces ensure clean, interference-free connections to inverters, controllers, and energy management systems.

Frequently Asked Questions

Yes. Our wiring solutions use UV-stabilized insulation, weather-sealed connectors, and high-flex cables to resist heat, cold, moisture, and mechanical stress, ensuring long-term outdoor reliability.

Absolutely. We offer full customization based on your electrical drawings, cable routing paths, connector types, and voltage/current requirements for solar inverters or wind turbine platforms.

Our products comply with UL, TUV, RoHS, REACH, and other international standards. All components are tested for insulation, flame resistance, and mechanical durability, meeting global utility and EPC project needs.

We implement barcode tracking, full-process inspection, and can provide PPAP or test reports upon request. For mass deployment, we ensure consistent quality across every harness delivered.

Yes. We offer pre-labeled, plug-and-play harness kits customized to your site layout, reducing onsite wiring time and minimizing human error during installation.

For standard designs, our lead time is typically 10–15 business days. For customized bulk orders, we offer flexible scheduling and support phased deliveries to match your project timeline.