Precision Wiring for Life-Saving Technology

Engineered for precision, safety, and long-term reliability in medical devices.

Trusted Connections in Critical Care

- In the medical field, every connection matters. Whether it’s powering a surgical robot, transmitting signals from a patient monitor, or linking components in diagnostic systems—reliable wiring is mission-critical.

- At Infinite, we design and manufacture custom wiring harnesses and cable assemblies for medical imaging, patient monitoring, diagnostic instruments, lab equipment, and surgical systems. Our products meet stringent requirements for precision, EMI shielding, biocompatibility, and cleanliness.

- With traceable materials, ISO-compliant processes, and rapid prototyping capabilities, we help medical OEMs, startups, and device integrators bring safer, smarter, and more dependable healthcare technologies to life.

Get a Free Quote Now

Challenges & Solutions

Engineering for Precision, Cleanliness, and Compliance

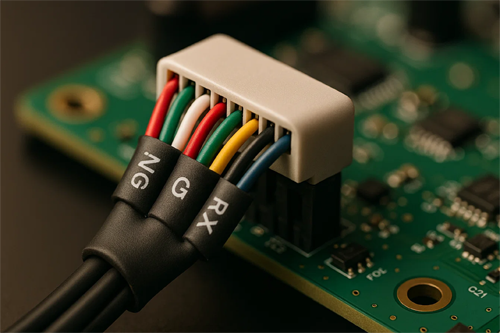

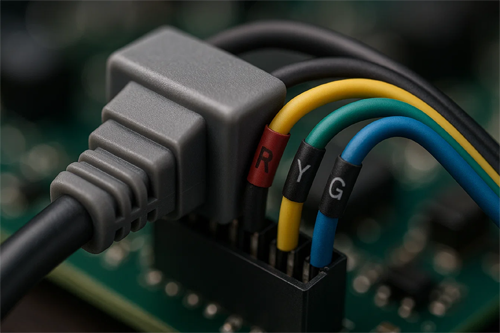

Signal Integrity in Sensitive Medical Devices

Challenge: Devices like ECG monitors, ultrasound machines, and diagnostics require clean, interference-free signal transmission.

Solution: We provide shielded, twisted-pair harnesses with proper grounding to reduce EMI and ensure reliable data flow.

Tight Space Constraints in Compact Devices

Challenge: Surgical tools, wearable monitors, and handheld devices have very limited internal space.

Solution: We offer ultra-thin, flexible wire harnesses with micro connectors and precise routing geometry.

Cleanroom and Sterilization Compatibility

Challenge: Harnesses used in surgical systems or lab equipment must tolerate sterilization and cleanroom conditions.

Solution: We use medical-grade materials with smooth jacketing, minimal outgassing, and compatibility with autoclave or ETO sterilization.

Biocompatibility for Patient-Contact Applications

Challenge: Cables that touch the patient require certified biocompatible insulation and coatings.

Solution: We offer harnesses built with ISO 10993-certified materials to ensure skin- and body-safe compliance.

Regulatory Documentation and Traceability

Challenge: Medical customers often require full documentation, material certificates, and lot-level traceability.

Solution: We provide compliance support including RoHS, REACH, FDA-grade materials, full batch records, and PPAP documentation.

Low-Volume, High-Mix Customization Needs

Challenge: Many medical applications involve low-MOQ, high-mix wiring needs for unique devices or R&D.

Solution: Our flexible production lines and rapid prototyping services support quick turnaround and full customization—even in small volumes.

Typical Applications

Where Reliability Meets Clinical Precision

Patient Monitoring Systems

Signal harnesses used in ECG, SpO2, and multiparameter monitors to transmit vital signs with zero noise or delay.

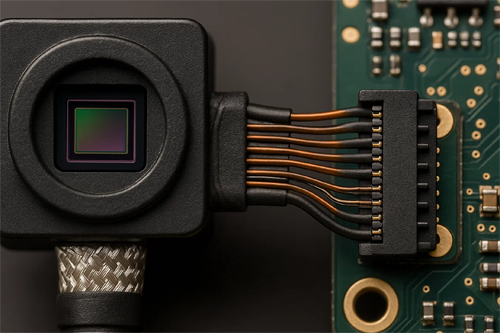

Diagnostic Imaging Equipment

Cables connecting sensors, motion modules, and image processors in MRI, CT, and ultrasound systems.

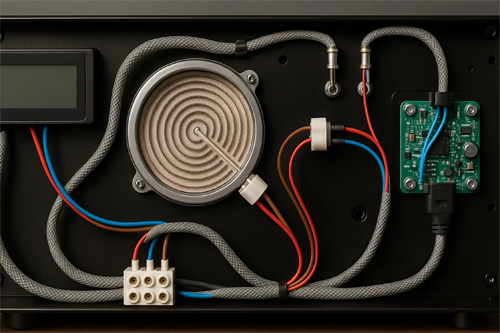

Surgical Robots & Tools

Flexible, sterilization-compatible harnesses for robotic arms, endoscopes, and powered surgical instruments.

Laboratory & Diagnostic

Wire assemblies for analyzers, centrifuges, incubators, and lab automation systems requiring precision control and low EMI.

Portable & Wearable Devices

Ultra-thin, lightweight harnesses used in Holter monitors, wearable ECG, and mobile diagnostic kits.

Infusion & Therapy Equipment

Power and signal harnesses for infusion pumps, dialysis systems, and therapeutic lasers requiring long runtime stability.

Precision You Can Trust in Every Connection

Custom wiring solutions for patient monitoring, imaging, diagnostics, and life-critical medical systems.

Feature Products

Purpose-built cable and wire harness solutions for compact, connected, and fast-moving consumer devices.

Patient Monitor Signal Harness

Shielded, low-noise signal harness for ECG, SpO2, and multiparameter monitoring equipment.

Flexible cable assembly for MRI, CT, and ultrasound systems, built for EMI resistance and precision.

Compact power and control harnesses designed for surgical tools, robotic arms, and motorized systems.

Ultra-thin, lightweight harnesses for Holter monitors, portable ECG, and wearable diagnostics.

Custom wiring kits for analyzers, incubators, and automated lab equipment.

Low-voltage harness for alarms, LEDs, and status indicators in medical machines.

What You Get

What Medical Innovators Gain by Partnering with Us

Medical-Grade Standards

Products are built using ISO 13485-compatible processes and medical-grade materials for safe use in clinical environments.

Clean Signal Transmission

We ensure clean signal transmission in sensitive devices like ECG, EEG, and ultrasound systems.

Fast Prototyping Support

Our fast-turn prototyping services support new device development and clinical trials with low-volume runs.

Compact Harness Design

Flexible and micro-wire harnesses are engineered to fit inside wearable and handheld medical devices.

Full Compliance & Traceability

We provide material declarations, RoHS/REACH statements, FDA material data, and batch-level traceability.

Low MOQ, High Flexibility

We accommodate small batch sizes and high-mix customization to serve diverse device configurations.

Reliable Long-Term Supply

We maintain stable production and supply chain reliability for lifecycle continuity of medical platforms.

Engineering Compliance Help

We assist clients with harness documentation, technical drawings, and DFM feedback for FDA or CE submission.

Frequently Asked Questions

Yes. We offer harnesses built with ISO 13485-compliant processes, and provide RoHS, REACH, and FDA-grade material declarations upon request.

Absolutely. We support quick-turn samples and small batch builds to help with clinical testing, design validation, or pilot production.

Yes. We use medical-grade materials that tolerate high-temperature sterilization and chemical disinfection when needed.

We use smooth-jacket cables with minimal outgassing and offer harnesses manufactured in ISO 7–8 clean environments.

Yes. We offer micro-wire solutions with 0.5–1.25mm pitch and miniature connector options for space-constrained applications.

We can provide PPAP, material traceability, test reports, and detailed drawings to support medical regulatory audits or OEM reviews.