Industrial & Robotics

Built for Precision. Ready for Tough Environments.

- In today’s high-tech manufacturing and automation environments, even a millisecond of delay or a single wiring fault can lead to costly downtime, production errors, or safety risks. That’s why industrial and robotics applications demand wiring harnesses that are not just accurate—but incredibly reliable.

- At Infinite Possibilities, we specialize in building custom wire harnesses for automation equipment, robotic arms, CNC machines, control panels, and motion control systems. Each harness is engineered to endure high-vibration, high-cycle, and high-load environments—while ensuring precision signal integrity and clean power delivery.

- We serve small to mid-sized manufacturers, integrators, and system builders who need fast prototyping, flexible volumes, and component-level customization. Whether you’re upgrading a line or building a new automation system, we’ll help you reduce risk, improve uptime, and bring your projects to market with confidence.

Get a Free Quote Now

Problems We Help Solve

Tailored harness designs that solve real problems in compact, connected electronics.

Frequent Vibration Damage

Issue: Continuous vibration from motors, conveyors, or robot joints can loosen terminals and break wires. How We Help: Reinforced crimping, strain reliefs, and vibration-tested materials reduce failure rates dramatically.

Complex Routing in Tight Spaces

Issue: Dense control panels and robotic arms leave little room for cable movement or routing. How We Help: We design slim-profile, flexible harnesses with labeled terminations for faster and safer installations.

High EMI Interference Risks

Issue: Factories with heavy machinery often suffer from electromagnetic interference affecting signals. How We Help: We build shielded harnesses with grounding layers to maintain data integrity and reduce signal loss.

Low Flex-Life in Moving Applications

Issue: Wires used in robotic arms or moving assemblies often break after repeated bending. How We Help: We use high-flex cables rated for millions of cycles, paired with optimized strain relief.

Long L/T and Mini Order Barriers

Issue: Many suppliers require high MOQs or have slow lead times for custom harnesses. How We Help: We specialize in low-volume orders with fast prototyping, ideal for small-batch automation projects.

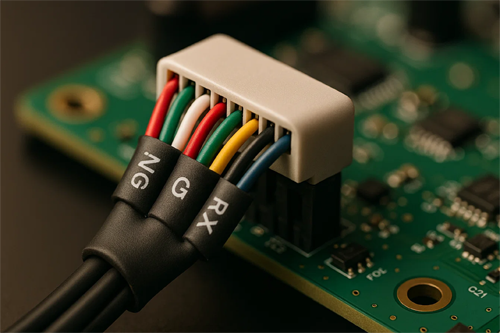

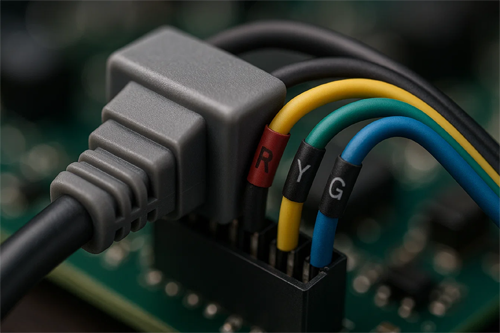

During Maintenance or Upgrades

Issue: In complex industrial systems, unlabeled or confusing harness layouts lead to miswiring, increased downtime, and troubleshooting costs. How We Help: We provide clearly labeled harnesses with color-coding, numbered connectors, and complete wiring diagrams to simplify maintenance and reduce errors.

Typical Applications

Where Our Wiring Solutions Power Industrial Precision

Robotic Arms & Automation Systems

Flexible, high-flex-life harnesses that withstand repetitive motion, support multi-axis control, and integrate sensors, actuators, and feedback loops with precision.

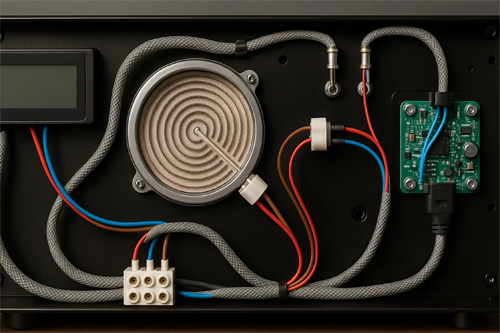

CNC Machines & Motion Control

Shielded, vibration-resistant harnesses for high-precision machining, servomotor control, and real-time signal feedback under constant stress.

Industrial Control Panels & PLC Systems

Custom harness kits for clean power distribution, signal communication, and panel-to-device connections—pre-labeled and ready for plug-and-play assembly.

Smart Factory & Logistics Systems

Reliable cabling for conveyors, pick-and-place arms, AGVs, and warehouse automation—designed for harsh use and high uptime environments.

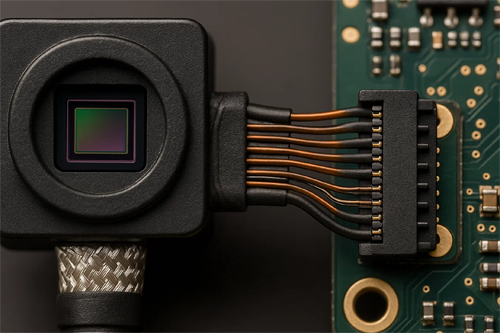

Vision & Sensing Systems

Low-noise harnesses for data transmission between industrial cameras, proximity sensors, and inspection modules—minimizing EMI and latency.

Collaborative Robots & Modular

Modular harnesses for compact, reconfigurable systems—supporting tight bends, quick swaps, and low-profile routing.

Wiring Built for Motion. Performance Built for Industry

Flexible, shielded, and vibration-resistant harnesses—made for robots, CNCs, and automated systems.

Feature Products

Purpose-built cable and wire harness solutions for compact, connected, and fast-moving consumer devices.

Signal and power distribution for PLCs, I/O modules, and drive systems—engineered for tight spaces and clean panel layout.

High-Flex Cable Assemblies

Designed for millions of bend cycles—ideal for robotic joints, sliding actuators, and dynamic motion systems.

Shielded and grounded assemblies for EMI-sensitive feedback, sensor, and encoder wiring.

Compact, space-saving cables for internal control panels and low-profile modules.

Retractable spiral cables for robotic arms, handheld tools, or mobile workstations.

Multi-outlet assemblies for complex systems—pre-configured to reduce routing errors and save install time.

What You Get

Wiring solutions designed for fast-moving consumer tech.

Fit for Complex Assemblies

Each harness is built to exact specs—lengths, bends, and connector orientations—to fit seamlessly into tight and multi-axis robotic structures.

Simplified Cable Routing

We design flat, labeled, and modular harnesses that make routing inside control cabinets faster and cleaner.

Built for Motion – High Flex Life

Use of ultra-flexible cable and optimized strain relief ensures millions of movement cycles without failure.

Engineering Collaboration

We work directly with your design team to co-develop routing plans, connector choices, and DFM improvements.

EMI-Resistant Signal Stability

Full shielding + grounding protects sensors, motors, and feedback systems from industrial electromagnetic noise.

Faster Mechanical Assembly

Pre-terminated harnesses with connector keying and clear labeling reduce install time and assembly errors on the line.

Small Batch, High Consistency

Even in low-volume runs, we ensure high part consistency and repeatability for robotic OEMs and automation startups.

Easy Maintenance & Replacement

Designed with quick-disconnect modules and maintenance-friendly layouts for fast servicing without disassembling your entire robot.

Frequently Asked Questions

Yes. We offer high-flex cable assemblies rated for millions of cycles, ideal for multi-axis robots, sliding actuators, and repetitive-motion environments.

Every harness is labeled, color-coded, and available in modular formats. We also provide wiring diagrams and pin-out charts to simplify installation.

No problem. We support custom connector sourcing and pin mapping—even for unique or legacy interfaces. Just send your drawings or samples.

All builds, large or small, follow the same ISO 9001-certified process with 100% continuity testing, documentation, and traceability for repeatable quality.

Absolutely. We support early-stage engineering collaboration to optimize routing, stress relief, and manufacturability—at no extra cost.

Yes. We manufacture fully shielded, grounded harnesses designed for encoders, sensors, and control systems operating in high-EMI zones.