Powering the Future of E-Mobility & Energy Storage

From high-voltage EV battery harnesses to smart BMS wiring, our solutions are built for safety, precision, and scalable electrification.

Smart Connections for Smarter Devices

- As electric vehicles and advanced battery systems scale globally, the wiring inside them becomes increasingly mission-critical. High voltage, high current, thermal stress, and space constraints make EV & battery harness design a specialized challenge.

- At Infinite, we deliver custom wire harnesses and cable assemblies for EV powertrains, battery packs, BMS (Battery Management Systems), charging modules, and energy storage systems. Our solutions are built to handle high power loads, resist vibration and heat, and integrate seamlessly with OEM components.

- Whether you’re building passenger EVs, electric two-wheelers, or grid-scale storage units, we help you wire safer, smarter, and faster—enabling the next generation of clean mobility and distributed power.

Get a Free Quote Now

Challenges & Solutions

Solving the Complexities of EV & Battery Wiring

High Voltage and Current Transmission

Challenge: EV and battery systems require harnesses to handle up to 800V and high continuous current without overheating.

Solution: We use thick-gauge, high-temp rated cables with insulation and terminal systems designed for HV safety, stability, and minimal power loss.

Limited Space in Battery Packs and EV Platforms

Challenge: Modern EV designs require complex routing in confined areas with tight bend radii.

Solution: We provide ultra-flexible cable assemblies with compact sealing components and optimized harness geometry.

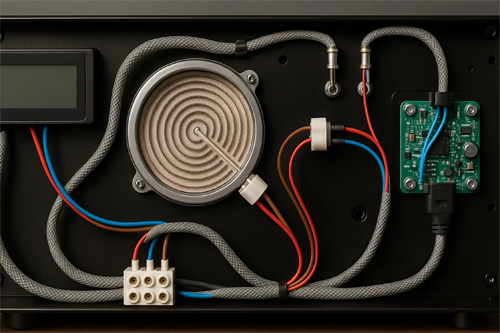

Heat and Vibration Stress

Challenge: Battery environments experience continuous thermal cycling and mechanical vibration, which can cause wire fatigue.

Solution: Our harnesses are tested for vibration resistance, thermal cycling, and are jacketed with abrasion- and heat-resistant materials.

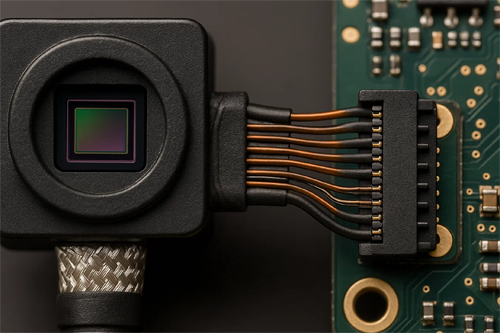

EMI and Signal Interference

Challenge: BMS and EV control systems require accurate data transmission and are sensitive to noise.

Solution: We offer shielded signal cables, twisted-pair layouts, and proper grounding schemes to ensure data integrity.

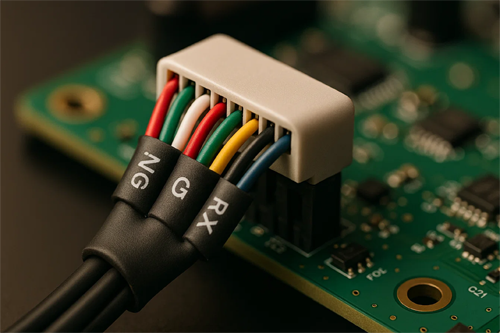

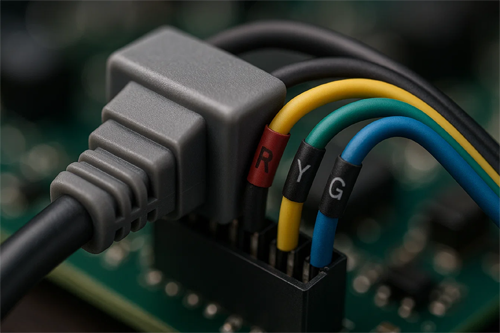

Connector Reliability under Harsh Use

Challenge: EV connectors undergo repeated mating cycles, exposure to moisture, and high current.

Solution: We source automotive-grade sealed connectors with high mating life and IP-rated environmental protection.

Scaling Production with Evolving Battery Designs

Challenge: Battery module designs and interfaces change frequently in new EV platforms.

Solution: Our agile engineering team supports rapid prototyping, connector changes, and BOM flexibility for fast design adaptation.

EV & Battery Applications

Where Safety, Power, and Precision Meet

EV Battery Pack Wiring

Custom harnesses designed to connect cells, modules, BMS, and thermal sensors within EV battery packs.

High Voltage Interconnects

Thick-gauge, high-insulation harnesses for linking inverters, battery disconnect units, and power distribution boxes.

Battery Management System

Signal and sensor harnesses supporting voltage, current, and temperature monitoring across cells and modules.

EV Charging Port Harness

Robust assemblies that connect onboard chargers, charging ports, and power relays.

Electric Two-Wheeler Drive Wiring

Compact power and control harnesses for scooters, e-bikes, and light EVs with space-constrained layouts.

Energy Storage System (ESS) Cabling

High-current cables for battery cabinet modules and control units in grid-scale or commercial ESS setups.

Wiring the Power Behind Every Electric Revolution

From high-voltage EV drive systems to scalable battery storage networks, our harnesses deliver the safety, precision, and durability your innovations demand.

Feature Products

Wiring Solutions Built for High Voltage, High Stakes

High-Voltage Battery Interconnect

Robust, high-current harnesses connecting battery modules, junction boxes, and disconnect units, rated for up to 800V.

BMS Signal & Sensor Harness

Twisted-pair, shielded harnesses for voltage sensing, thermal monitoring, and CAN communication between modules and BMS.

EV Powertrain Cable Assembly

Flexible, high-temperature cable assemblies linking inverters, motors, and battery packs with low-loss delivery.

Onboard Charger (OBC) Wiring Kit

Shielded power and signal harnesses connecting AC charge ports to onboard chargers and battery input units.

EV Charging Port Interface Cable

Sealed, weather-resistant cable assembly for fast-charging inlet ports, supporting multiple charging standards.

Energy Storage System (ESS) Cabinet

High-current, UL-compliant harnesses for power distribution inside battery storage cabinets and control racks.

What You Gain with Smarter EV & Battery Harnesses

Delivering Safety, Performance, and Scalable Integration for EV and Battery System Manufacturers Worldwide.

Safer High-Voltage Connections

All harnesses are designed to handle 300V–800V safely, using insulation, shielding, and anti-tracking materials that minimize arc risk.

Increased System Efficiency

Low-resistance cables and optimized routing help reduce energy loss between battery, inverter, and motor components.

Compact Integration

Harnesses are tailored to fit into tight compartments and support modular battery and drive system designs.

Enhanced EMI Shielding for BMS

Twisted-pair signal lines and shielding techniques maintain clean, interference-free BMS communication.

Faster EV Production Ramp-Up

Pre-terminated harness kits reduce assembly time and simplify installation on EV production lines.

Field-Proven Durability

All assemblies are tested for thermal cycling, vibration, and connector fatigue to ensure long-term reliability.

Global Compliance for Standards

Products meet ISO 19642, IATF 16949, RoHS, and UL requirements, supporting international EV platforms.

Engineering Support for Custom

We offer co-design, prototyping, and design-for-manufacturing (DFM) support to accelerate development and reduce redesign cycles.

Frequently Asked Questions

Yes. Our high-voltage harnesses are rated up to 800V DC and built with insulation, shielding, and connector systems that meet automotive-grade safety standards.

Absolutely. We support full customization, including cable lengths, connector types, pinouts, and routing geometry to match various EV architectures and battery formats.

Yes. Our harnesses meet ISO 19642, IATF 16949, UL 758, RoHS, and other global standards required for EV and battery system integration.

We conduct vibration, thermal cycling, salt spray, and connector fatigue tests to ensure reliability in real-world EV operating environments.

Yes. We offer rapid prototyping and small-batch samples with fast lead times to support R&D, design validation, and pilot production phases.

Yes. Our signal harnesses are optimized for BMS voltage, current, and temperature feedback, and support CAN, LIN, or UART communication interfaces.