Custom Wiring Harness Manufacturing: 7 Key Questions to Ask Your Supplier

Table of Contents

ToggleCustom Wiring Harness Manufacturing: 7 Key Questions to Ask Your Supplier

Selecting the right custom wiring harness manufacturer is crucial for ensuring product reliability, safety, and performance. Suppliers vary widely in their expertise, capabilities, and processes. To make an informed decision, engineers and procurement professionals should ask targeted questions that reveal a supplier’s experience, technical skills, and quality practices. Here are seven key questions to guide the evaluation of a wiring harness supplier.

1. Do you have experience in our industry (Automotive & E-Mobility, Medical & Healthcare, Industrial & Robotics)?

Different industries have unique requirements and standards. A harness maker who has worked in your sector will better understand the challenges and regulations involved. For example, Infinite Possibilities highlights its work in automotive, consumer electronics, medical devices, and industrial automation. In practice, automotive and e-mobility applications may demand EV-rated, vibration-resistant harnesses (think engine wiring harnesses or 4-pin trailer wiring harnesses), while medical and healthcare projects often require ultra-reliable, highly miniaturized cables. You should ask if the supplier has built harnesses for applications like cars, EVs, or medical equipment. They should be able to share case studies or example designs (even a simple wiring harness diagram) to prove their capability. Checking references and past client portfolios can also confirm their experience.

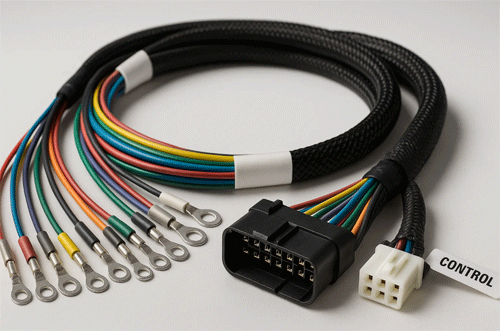

In Industrial & Robotics applications, harnesses often branch out to multiple components. The image above shows a harness used in a robotic system, connecting power and signals to motors, sensors, and a LiDAR module. This illustrates the complexity a harness might have in robotics or automation. A capable supplier should demonstrate experience with such multi-branch, vibration-tolerant designs. In fact, companies like Infinite Possibilities emphasize that their harnesses are designed to withstand harsh environments and meet automotive-grade standards. Verifying industry expertise ensures the supplier can meet any specialized requirements of your project.

2. What types of harnesses and cable assemblies can you manufacture?

Evaluate whether the supplier’s product range includes the specific types you need. Common categories include:

-

Custom Wiring Harness – Fully tailored harnesses designed exactly to your specifications. These may combine power, signal, and ground wires into one assembly for a unique device or system. A good custom harness will simplify installation and reduce assembly errors.

-

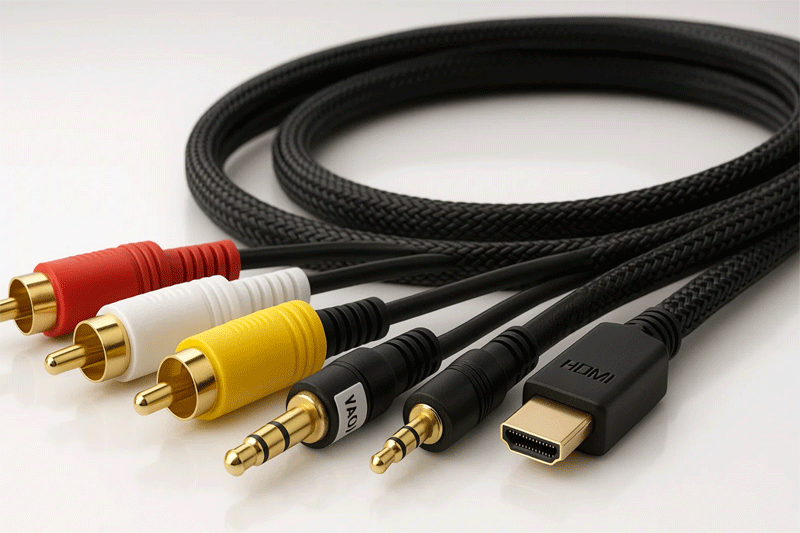

Signal & AV Wire Harness – Harnesses built for audio, video, and data transmission. These assemblies often include shielded or twisted-pair cables for low-loss performance, as noted in Infinite’s Signal & AV Wire Harness product page. If your project involves cameras, sensors, or media devices, ensure the supplier can handle high-speed signals and proper shielding.

-

Control Wire Harness – Harnesses used in industrial machines, robotics, or vehicles to connect control units, actuators, and sensors. These often carry power and I/O signals in rugged environments. Ask if they can produce harnesses to match standard protocols (CAN bus, Ethernet, etc.) if needed.

-

Additional Assemblies – Some suppliers also offer flat ribbon cables, molded cable assemblies, power cords, or specialty harnesses. Confirm the available options (e.g., custom cable overmolding, shielded cables, custom cable assemblies) to ensure they cover any specialized format your application might require.

In short, the supplier should clearly list the types of wiring harnesses and cable assemblies they build. This ensures they can meet your project needs rather than forcing you to adapt your design to their limited catalog.

3. What manufacturing capabilities and services do you provide (Overmolding Services, Flexible Manufacturing, Tests & Inspections)?

Ask about the factory’s technical strengths and in-house services, since these impact lead time and product quality:

-

Overmolding Services – Can the supplier encapsulate connectors and wire ends with molded plastic or rubber? Overmolding is a valuable process that adds strain relief and environmental protection. Cable overmolding produces a single, seamless assembly that is impervious to dust, moisture, and vibration. This dramatically increases durability (cables can withstand shock and flexing) and simplifies assembly for your team.

-

Flexible Manufacturing – Will the manufacturer quickly adapt to changes or prototype runs? A “flexible manufacturing” capability means they can handle low- to medium-volume orders and design tweaks without huge delays. For example, Infinite Possibilities boasts an agile workflow that adapts quickly to last-minute design updates. Flexibility is especially important if you expect engineering iterations or small-batch production.

-

Tests & Inspections – Every harness should be tested and inspected before shipment. Ask if they perform 100% electrical testing (continuity, hipot, etc.), mechanical pull tests, and visual checks. Thorough Tests & Inspections ensure each unit meets your specifications and can highlight defects early. Reliable suppliers will have dedicated quality stations and can share their testing protocols.

Also inquire about additional services like laser marking, cable labeling, or custom assembly fixtures. A well-equipped factory will often offer a suite of capabilities (e.g. crimp machines, soldering automation, and assembly tools) that speed up production and maintain consistency.

4. How do you ensure quality and compliance (Quality Guarantee, certifications)?

Quality is paramount for wiring harnesses, which often power critical systems. Key points to cover:

-

Quality Guarantee – Does the supplier have a formal quality policy or warranty? Many reputable manufacturers guarantee that each harness will be free from defects and meet all requirements. For example, Infinite Possibilities stresses “Full Quality Assurance” with every unit tested and traceable. Confirm how they define their guarantee (e.g., replacement of faulty parts, corrective measures) and what documentation they provide (inspection reports, test data).

-

Certifications and Standards – Check for recognized certifications. ISO 9001 certification indicates a robust quality management system. Indeed, Infinite Possibilities notes it is ISO 9001:2015 certified. Similarly, look for UL or CE marks on products, which show compliance with electrical safety standards. In specialized fields, there may be more requirements (e.g. IPC-A-610 training for assembly, RoHS/REACH for materials, or specific medical device standards). Verifying these qualifications protects you from regulatory issues.

-

Inspection Processes – Ask how they control quality during production. Do they inspect incoming materials? Are harnesses 100% inspected visually or with automated optical systems? The supplier should also trace every batch of wires and connectors, so issues can be traced back to source materials or machines.

By demanding a Quality Guarantee and appropriate certifications, you protect your project against recalls, failures in the field, and non-compliance. Don’t hesitate to ask for copies of their certificates or audit reports if needed.

5. What are your lead times and production flexibility (Quick Turn Available)?

Time-to-market is often critical. Clarify how quickly the supplier can deliver and how they handle capacity:

-

Quick Turn Available – Can they accommodate fast prototypes or urgent orders? Ask for concrete examples of lead times. Some suppliers (like Infinite) even publish rapid turnaround targets, such as 2–3 weeks for custom harnesses. If you have tight deadlines, ensure “Quick Turn Available” is part of their offering. Understand which phases of production are expedited – for example, they may reserve quick-turn capacity for prototypes but require longer notice for large production.

-

Production Capacity – What is their typical production volume range? If you start with a small batch, confirm they can also scale up if your orders grow. Manufacturers sometimes reserve capacity or have flexible shifts to meet demand; Infinite, for instance, mentions agile manufacturing and reserved production capacity to meet tight deadlines. Ask about their current workload and how they plan projects to avoid bottlenecks.

-

Low-Volume & Prototyping – If you need prototypes or a pilot run, ensure they handle small orders. A supplier specializing in small-batch custom work will welcome prototypes without forcing a large minimum order. Confirm their minimum order quantity and see if the price per unit is reasonable for small runs.

-

Stock and Components – Delays often come from long lead-times on special wires or connectors. Check if the supplier stocks common components or has fast sources. Some factories maintain inventories of standard wire, connectors, and terminals to shorten lead time. If they need to source parts for you, ask how they handle that process and if it adds to the schedule.

Understanding lead times and flexibility upfront prevents surprises later. A transparent supplier will clearly state their capabilities and even offer expedited options if needed.

6. How will we collaborate on design and how responsive is your technical support (Strong Technical Support)?

Smooth communication and expert support can make or break a project. Key aspects:

-

Strong Technical Support – Will the supplier review your design and offer suggestions? Good manufacturers have application engineers or technical reps to guide the process. For example, Infinite says their expert team assists with design review, material selection, and prototyping. Ask if they can help optimize the harness design – for instance, suggesting better routing, connector choices, or wire gauges for your application.

-

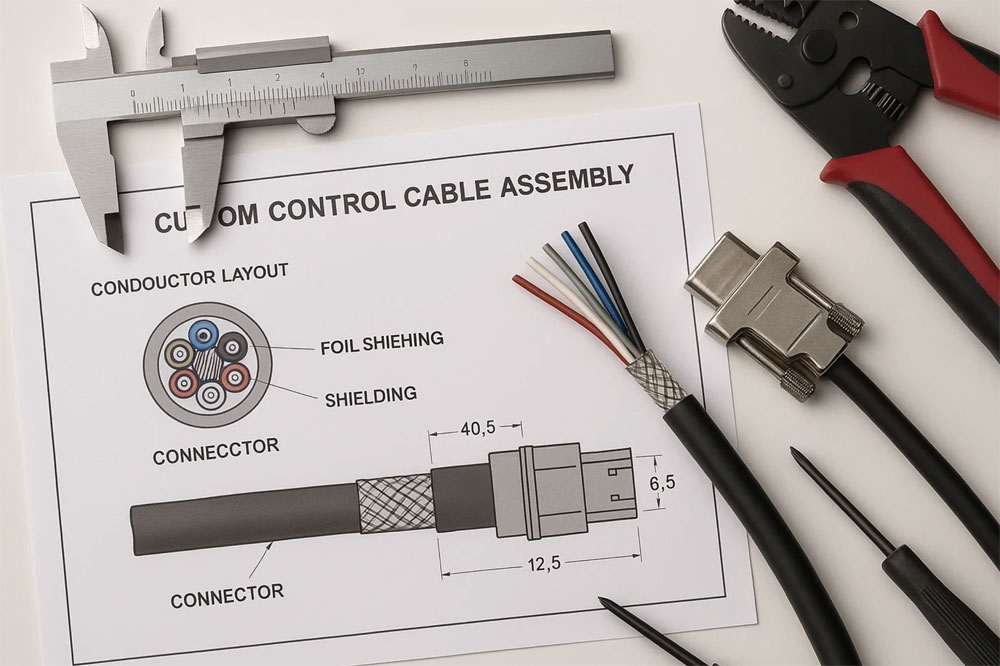

Documentation and Drawings – The supplier should provide clear documentation. Request that they create or share a wiring harness diagram (schematic) or assembly drawing before production. This diagram should label each wire color, pinout, and connection. Reviewing this ensures everyone agrees on the design. High-quality factories often deliver a documented record with each batch (including a bill of materials and test results).

-

Communication & Updates – How quickly will they answer questions and update you on progress? For international projects, prompt response is vital. Check if they offer a dedicated contact person, or even 24/7 support. Infinite emphasizes a “global service mindset” with prompt replies and clear updates. You might also ask if they use project management tools, weekly reports, or provide samples/photos during production. The more transparent their communication, the fewer misunderstandings.

-

Troubleshooting and After-sales – What happens if a harness fails or needs revision? Understand their policy for rework or warranty. Reputable suppliers will work with you to fix issues (for example, by replacing defective parts or adjusting the design) rather than blaming the customer. Confirm their process for any returns or repairs after delivery.

In essence, your supplier should act as an engineering partner, not just a contract manufacturer. Strong technical collaboration and open communication will save time and ensure the harness meets all requirements.

7. Are your prices transparent and can we build a long-term partnership?

Finally, clarify commercial and relationship factors:

-

Transparent Quotes – Ensure the supplier’s quotes cover all costs. A trustworthy supplier will provide a detailed breakdown of costs (materials, labor, tooling, testing). Infinite highlights that its quotes are “detailed and transparent” with “no hidden fees”. Make sure your quote covers everything you expect – including costs for design changes, prototypes, or low-volume surcharges – to avoid surprises later.

-

Volume Discounts & Terms – Ask if pricing scales with volume or if there are bulk discounts. Also discuss payment and delivery terms. A stable manufacturer often offers favorable terms (net payment, deposit, etc.) once a partnership is established. Verify if there are any unusual policies (like very high minimum orders or cash-only terms) that might indicate inflexibility.

-

Reliability and Consistency – Consider the supplier’s stability and reputation. Will they be able to support your future needs over the years? Look at their client list or tenure in business. Longevity and consistency (such as stable lead times over many orders) are good signs. You can also inquire about potential “no hidden costs” – make sure escalation in material costs or currency changes are handled fairly and documented in contracts.

-

Customer References – Don’t hesitate to ask for references or case studies. Hearing directly from other customers about their experience can provide assurance. As an industry guide notes, “You should ask for references from every wire harness manufacturer you are serious about working with… talk about their experience working with the manufacturer”. If references consistently praise the supplier’s timeliness and quality, that bodes well for your relationship.

Building a long-term partnership means the supplier should align with your goals, whether that’s rapid innovation, tight budgets, or high-volume consistency. By confirming transparency and reliability, you set the stage for a smooth collaboration.

Summary:

Choosing the right custom wiring harness manufacturer involves more than just pricing. By asking the above questions – about industry experience, product range, technical capabilities, quality systems, delivery, support, and pricing – you gain a clear picture of a supplier’s strengths. Look for a supplier with relevant Automotive & E-Mobility, Medical & Healthcare, or Industrial & Robotics experience, a broad product lineup (including Custom Wiring Harness and other assemblies), and strong engineering support throughout the project. Also ensure they have a robust Quality Guarantee and credentials (like ISO 9001, UL, CE) to meet standards, can meet your schedule (Quick Turn Available if needed), and will communicate clearly with you (Strong Technical Support).

In the end, a thorough vetting process ensures you choose a partner who will deliver reliable, high-quality wiring harnesses on time and on budget, helping your products succeed in the field.

Ready to Vet Your Next Supplier?

If these seven questions sparked ideas—or revealed gaps—in your current sourcing process, let’s continue the conversation. Our engineering team is happy to review your drawings, suggest materials, or ship a Quick Turn prototype so you can see our quality first-hand.

-

Explore our full range of Custom Wiring Harness and Control Wire Harness solutions.

-

Learn how our Assembly Capabilities and in-house Overmolding Services shorten lead time while protecting critical connections.

-

Or reach out directly through the Contact page for fast, expert guidance from our Strong Technical Support staff.

Get in touch today and turn those questions into confident answers—one reliable harness at a time.