Control Cable Assemblies

Control Cable Assemblies – Reliable Signals. Confident Systems

Control cable assemblies are the backbone of automation and intelligent equipment. Whether you’re triggering actuators, monitoring sensors, or managing multi-point signals, even the slightest delay or interference can lead to system instability. That’s why high-quality control wiring is essential.

At Infinite Possibilities, we specialize in custom-built control cable assemblies engineered for signal clarity, mechanical reliability, and real-world performance. From single-core to multi-core, we support tailored conductor layouts, EMI shielding, and ruggedized terminations—all with no MOQ, fast prototyping, and full engineering support.

When your control system depends on precision, we help you deliver it—faster, cleaner, and with fewer failures. Whether you’re building machines, panels, or embedded systems, we make sure your cables don’t just connect—they perform.

Get a Free Quote Now

Engineered for Control, Designed for Confidence

More than just connectivity—our control cables are built to deliver accuracy, durability, and stability where it matters most.

Multi-Core Precision Wiring

Supports 2–30+ conductors with custom colors, pinouts, and bundling—simplifies routing and speeds up installation.

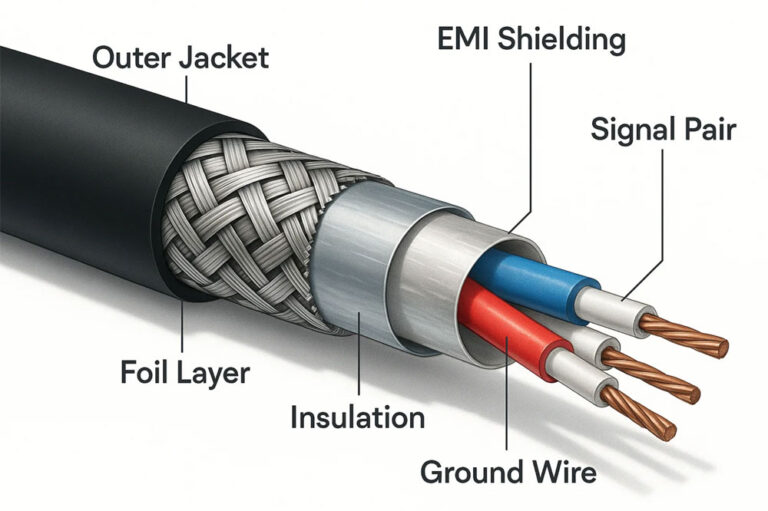

EMI Shielding & Grounding Options

Foil shielding, braided wire, or drain wire grounding to protect critical signals from interference. Ensures control accuracy in noisy environments.

Flexible + Rugged Cable Jacket Materials

PVC, PUR, or silicone jackets that withstand oil, abrasion, or motion stress without cracking. Ideal for harsh environments and repetitive motion.

Secure Crimping & Overmolded Strain Relief

Vibration-resistant terminations, sealed ends, and reinforced strain relief prevent disconnection. Avoids control failures from loose connections.

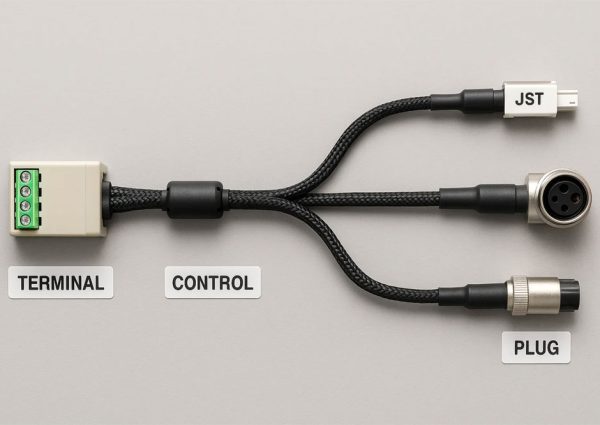

Modular & Multi-Branch Layouts

Add printed labels, ID sleeves, or plug-in terminal blocks for quick field installation. Minimizes errors and accelerates system commissioning.

Typical Applications

Trusted in Systems That Can’t Afford to Fail

Smart Traffic & Signal Systems

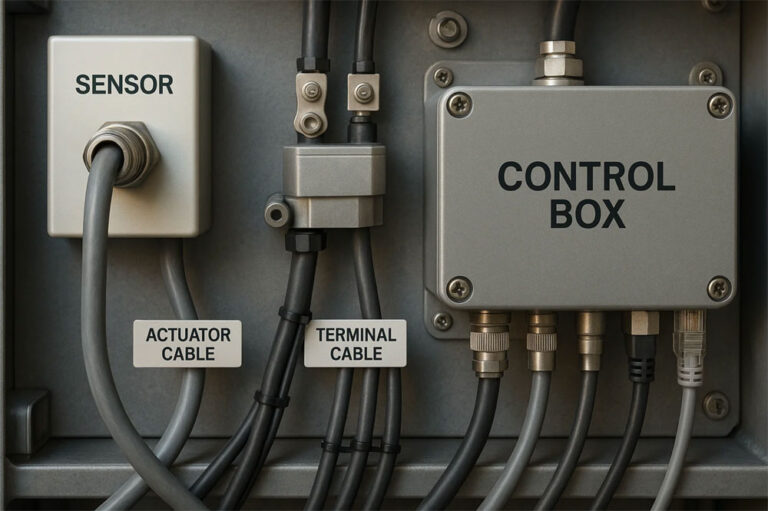

Pre-terminated control cables simplify field installation for light poles, sensors, and control boxes.

Robotics & End Effectors

Flexible cables for motion control and end-of-arm tooling, with strain relief and compact routing through joints.

Medical Equipment Control Units

Reliable wiring for imaging systems, surgical machines, and diagnostics—built with clean labels and secure terminations.

Industrial Automation Cabinets

Multi-core control cables connect PLCs, relays, sensors, and drives—ensuring clean layout and signal reliability in enclosed spaces.

Construction & Heavy Equipment

Ruggedized assemblies for joysticks, hydraulic valves, and safety switches—resistant to oil, shock, and motion stress.

Elevator & Building Systems

Flat or flexible control cables route between floors and panels, with anti-vibration design for long-term durability.

What You Get

Control Systems Perform Better When the Cables Do Too

Fewer Wiring Errors, Faster Installation

Custom layouts, clear labels, and pre-terminated ends eliminate guesswork and reduce installation time.

More Stable Signals, Less Downtime

Shielded designs and rugged terminations ensure low EMI and solid connection—even in harsh environments.

Fits System, Not the Other Way Around

Flexible conductor count, pinout, and jacket options ensure the cable fits your actual design—no compromise.

Lower MOQ, Higher Flexibility

Whether you need 10 cables or 1000, we offer the same support—ideal for prototyping, small series, or design changes.

Frequently Asked Questions

Yes. We support hybrid assemblies with both signal and low-voltage power lines, fully isolated and labeled.

Absolutely. Just share the port or connector specs—we’ll match the exact terminal type, pitch, and pinout layout.

Yes. We build fully customized cables with EMI shielding, multi-branch routing, and printed labels—all in one assembly.

Typically up to 30–40 conductors per bundle, depending on cable diameter and bend radius requirements.

No problem. We support low-volume prototyping with full technical support and fast turnaround.