Automotive & E-Mobility

Powering the Future of Mobility

Custom wiring solutions for modern vehicles—built for safety, performance, and electrification.

- The Challenge:The automotive and e-mobility industries are undergoing rapid transformation. With more electronics, sensors, and EV systems packed into tighter spaces, the demand for reliable, compact, and high-performance wiring harnesses has never been higher.

- Our Role:At Infinite Possibilities, we engineer custom wire harnesses that meet the exacting needs of both traditional vehicles and next-generation EVs. From battery interconnects to sensor networks and control units, our solutions are designed for harsh environments, vibration resistance, and compliance with global automotive standards.

- Our Advantage:Whether you’re developing electric motorcycles, hybrid cars, or autonomous vehicles, our team provides responsive support, fast prototyping, and scalable production. We help streamline your supply chain, accelerate certification, and ensure long-term reliability for critical systems.

Get a Free Quote Now

What Problems We Solve

Solving the wiring challenges behind safer, smarter, and more electrified vehicles.

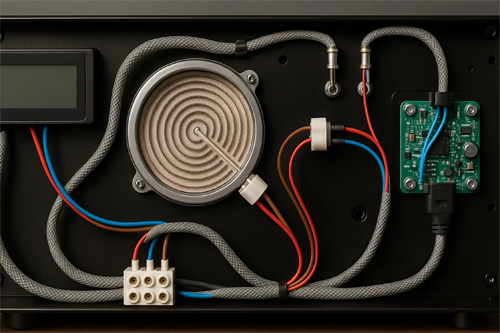

High-Voltage Safety & Compliance

We deliver wire harnesses rated for EV battery systems, designed for insulation, heat resistance, and full compliance with automotive safety standards.

Optimized Power Distribution

Custom cable assemblies for efficient power routing to motors, inverters, charging systems, and control units.

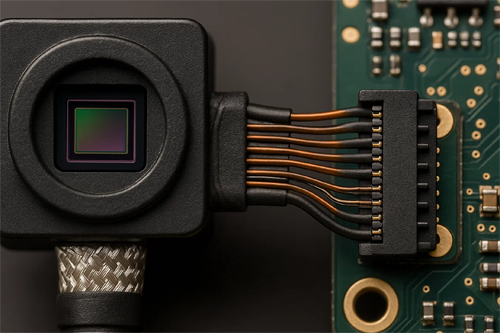

Sensor & Data Signal Integration

Designed to carry signals from cameras, radars, LIDARs, and sensors—ensuring accurate ADAS and vehicle automation performance.

Tight-Space Routing Solutions

Thin-wall and multi-core harnesses that fit into compact automotive interiors and battery compartments.

Modular System Compatibility

Harnesses tailored to specific vehicle modules—dashboards, charging ports, steering systems—for seamless plug-and-play integration.

Support for Fast Prototyping & EV Startups

From prototype harnesses to pilot runs, we offer short lead times and engineering support for new-energy vehicle projects.

Recommended Wiring Solutions

Built to power the next generation of vehicles.

Battery & High-Voltage Harnesses

Designed for EV battery packs, powertrains, and inverters—featuring thick insulation, heat shielding, and secure terminations.

Charging System Harnesses

Custom cable assemblies for AC/DC charging ports, onboard chargers, and external power interfaces.

Sensor & ADAS Wiring

Shielded signal harnesses for cameras, radars, ultrasonic sensors, and LIDAR units to ensure precise data transmission.

Interior Control Harnesses

Multi-branch harnesses for dashboards, infotainment systems, seat controls, and lighting modules.

Motor & Actuator Harnesses

Heavy-duty power and control harnesses for electric drive motors, HVAC actuators, and steering systems.

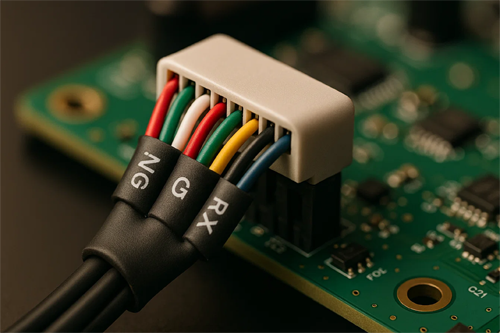

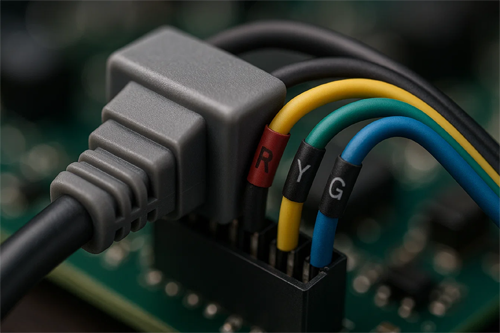

CAN/LIN Communication Harnesses

Low-voltage signal harnesses designed for reliable data exchange between ECU modules.

Smart Wiring for Smarter Devices

Tailor-made harness solutions for your fast-evolving consumer tech.

Feature Products

Purpose-built cable and wire harness solutions for compact, connected, and fast-moving consumer devices.

Multi-branch harnesses for dashboards, body control modules, HVAC, and interior electronics.

Shielded cables for cameras, ADAS systems, parking sensors, and feedback loops.

CAN/LIN Communication Harnesses

Robust, low-voltage harnesses for reliable ECU-to-ECU communication in distributed vehicle architectures.

Charging Cable Assemblies

Custom assemblies for AC/DC charging interfaces and onboard charging systems.

Heavy-gauge harnesses for battery packs, inverters, and electric drive modules—engineered for high current and thermal durability.

Retractable, vibration-resistant cords for steering columns, trunk lids, charging doors, and movable modules.

What You Get

Wiring solutions designed for fast-moving consumer tech.

Safer High-Voltage Integration

Our harnesses are built with enhanced insulation, crimp sealing, and anti-tracking materials—ensuring safety in high-voltage EV systems.

Clean, Compact Installation

We design for tight spaces—dashboards, battery boxes, motor bays—delivering clean layouts and easy cable management.

High-Flex Options for Dynamic Parts

Harnesses used in trunk lids, seat modules, and actuators are tested for repeated bending, vibration, and durability.

Seamless System Integration

From charging to controls to displays, our harnesses are built to plug into OEM modules with high precision and reliability.

Ready for Rapid EV Prototyping

We support early-stage builds, with fast lead times, low MOQs, and engineering flexibility.

EMI Shielding for Signal Integrity

Full shielding, grounding, and cable separation design protect sensor and control signals from noise and interference.

Small Batch, High Consistency

Even low-volume builds are controlled for connector fit, crimp quality, and wiring accuracy—batch to batch.

Automotive-Grade Engineering Support

Our team understands vehicle architecture and works with your engineers to meet fit, function, and compliance targets.

Frequently Asked Questions

We provide a wide range of custom wire harnesses tailored for both internal combustion engine (ICE) vehicles and electric vehicles (EVs), including powertrain harnesses, battery connection harnesses, signal and sensor harnesses, and high-voltage assemblies. All harnesses are engineered for high reliability, heat resistance, vibration tolerance, and long-term performance in demanding environments.

Yes. We specialize in small to medium batch production with flexible tooling options. This makes us ideal for supporting R&D prototypes, startup EV brands, and special-purpose vehicles such as agricultural, mining, or recreational vehicles. Our agile supply chain ensures short lead times without compromising on quality.

Our harnesses undergo 100% electrical testing, insulation resistance verification, and are built with automotive-grade connectors and sheathing. This significantly reduces the risk of signal failure or power interruptions, lowering long-term maintenance costs and minimizing post-sale service issues for our clients.

Our vertically integrated production, in-house prototyping, and optimized material sourcing allow us to offer competitive pricing without sacrificing quality. Additionally, we help customers shorten development cycles and reduce sourcing complexity, leading to faster market entry and better ROI.

Absolutely. Our engineering team can assist in harness layout design, component selection, BOM optimization, and 3D model validation. Whether you’re building a conventional vehicle or designing an e-scooter, battery pack, or mobility robot, we offer technical guidance to help you build safe and scalable systems.

Yes. For global vehicle manufacturers and EV startups entering new markets, we provide harness localization services—including material substitutions, component sourcing alignment, and adaptation to regional standards. This helps reduce logistics costs, avoid unnecessary tariffs, and improve after-sales serviceability.