Agricultural & Outdoor

Built to Brave the Elements — Custom Wiring for Agricultural & Outdoor Equipment

- In fields, forests, and construction sites, machinery faces constant punishment—dust, UV, vibration, moisture, and temperature swings that standard wiring simply can’t survive. A single harness failure can halt harvest, stall a job site, or cost hours of lost productivity.

- That’s why Infinite Possibilities designs and manufactures custom wire harnesses engineered specifically for agricultural, landscaping, and outdoor power equipment. From heavy-duty waterproof seals to UV-stable jackets and vibration-proof crimps, every detail is chosen to keep your machines running, season after season.

- Whether you build tractors, sprayers, excavators, or autonomous field robots, we deliver low-MOQ, rapid-prototype harnesses that shorten your development cycle, simplify installation, and slash lifetime maintenance costs—so you can focus on growing your business, not troubleshooting wiring.

Get a Free Quote Now

Key Challenges & Our Wiring Solutions

Tailored harness designs that solve real problems in compact, connected electronics.

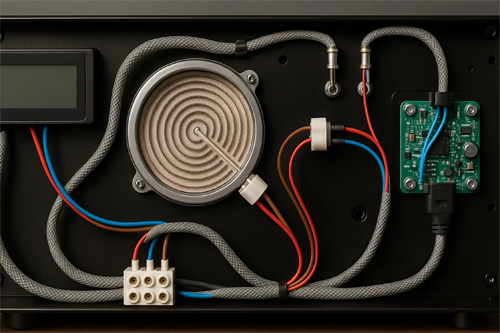

Extreme Weather Durability

Our harnesses utilize weather-resistant materials that withstand prolonged exposure to UV rays, rain, snow, and extreme temperature fluctuations—minimizing downtime and reducing maintenance costs.

Vibration & Shock Resistance

Advanced crimping, secure connectors, and flexible cable assemblies protect against vibration-induced damage, significantly improving equipment uptime and reliability.

Moisture & Corrosion Protection

We apply specialized sealing and protective coatings to prevent moisture ingress, corrosion, and short circuits—maintaining stable electrical performance even in wet or corrosive environments.

High-Load Power Delivery

Engineered with heavy-duty wiring and connectors, our harnesses reliably transmit high currents for motors, pumps, and hydraulic systems—reducing the risk of overheating and power loss.

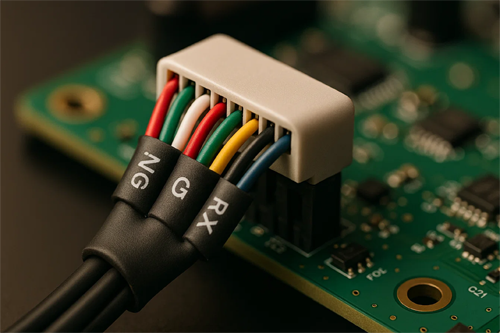

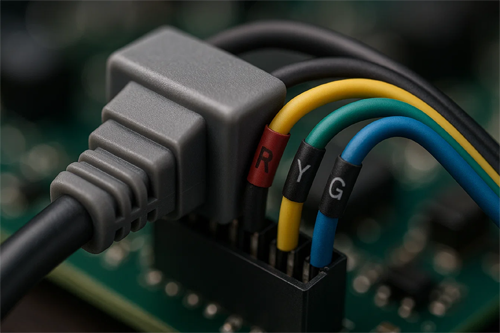

Simplified Installation & Maintenance

Harnesses feature clear labeling, plug-and-play connectors, and optimized layouts, reducing assembly time, installation errors, and future troubleshooting efforts.

Rapid Prototyping & Low MOQ Flexibility

Fast prototyping and support for low-volume orders allow agile product development and market responsiveness, helping you stay competitive without excess inventory costs.

Typical Applications in Consumer Electronics

Explore the common agricultural and outdoor equipment that benefits from our robust wiring harness solutions—ensuring efficiency, reliability, and longevity.

Tractors & Farm Equipment

Customized harnesses for engine control, hydraulic systems, and monitoring devices, improving operational reliability and simplifying field maintenance.

Precision Farming Technology

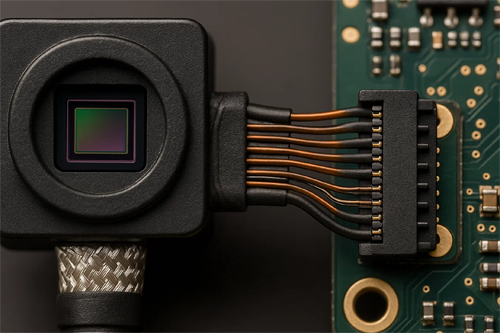

Advanced wiring solutions designed for GPS, sensors, and automated farming systems, providing accurate data transmission and reducing downtime.

Outdoor Power Equipment

Harnesses for lawn mowers, chainsaws, and outdoor generators, delivering durability and consistent performance even under harsh use.

Irrigation Systems

Waterproof and corrosion-resistant wiring tailored for automated irrigation controllers, pumps, and valves, ensuring long-lasting performance.

Agricultural Drones

Specialized lightweight and flexible wiring harnesses for drone propulsion, sensor integration, and data communication, supporting precision agriculture applications.

Forestry & Heavy Outdoor Machinery

Heavy-duty harnesses with enhanced abrasion and impact resistance, ensuring secure connections in logging equipment, excavators, and loaders.

Built Tough for Fields That Demand More

Rugged wiring harnesses engineered to boost reliability, minimize downtime, and enhance productivity.

Feature Products

Purpose-built cable and wire harness solutions for compact, connected, and fast-moving consumer devices.

Fully sealed and IP-rated for rain, wash-down, and mud-prone conditions.

Reinforced crimps and flexible layouts reduce wear from shaking machinery.

Built for high current loads in motors, pumps, and hydraulic systems.

Supports precise signal transmission for smart farming and automation.

UV & Weather-Resistant Jackets

Outdoor-rated materials resist cracking, fading, and insulation failure.

Speeds up field servicing and replacement with labeled, plug-in designs.

What You Get

Wiring solutions designed for fast-moving consumer tech.

Reduced Equipment Downtime

Rugged harnesses resist damage from weather, vibration, and debris—keeping machines running longer.

Lower Maintenance Costs

Durable, sealed materials prevent corrosion and failures, reducing repairs and service calls.

Faster Field Repairs

Modular designs and labeled cables simplify on-site maintenance and part replacement.

Improved End-User Satisfaction

Stable wiring equals fewer complaints, fewer returns, and stronger customer loyalty.

Faster Time-to-Market

Rapid prototyping and flexible production help you launch new models quickly.

Low MOQ for Custom Builds

No pressure to overstock—order exactly what you need, even for small or seasonal batches.

Easier Compliance & Documentation

Certified harnesses with UL, CE, and RoHS documentation for seamless approvals.

Trusted Engineering Support

Direct access to our technical team means faster answers, better designs, and fewer issues down the line.

Frequently Asked Questions

By using long-life materials, sealed connectors, and abrasion-resistant jackets, we cut failure rates and extend service intervals—resulting in lower lifetime maintenance and repair costs.

Absolutely. Our low-MOQ production model and scheduled delivery plans are built for seasonal industries—no excess stock, no storage burden.

Yes. We offer modular harness designs with labeled quick-connect terminals, enabling faster replacements and reducing downtime in the field.

We test for UV, vibration, moisture, and temperature extremes, and use materials certified for outdoor and agricultural-grade durability.

Definitely. Our engineers work directly with your team during the design phase to ensure ideal layout, cable length, and mounting for real-world installation.

Every harness comes with full specification sheets, material traceability, and test reports—ideal for CE, UL, and OEM field audit requirements.