Table of Contents

Toggle7 Essential Standards for Wire Harness Assemblies

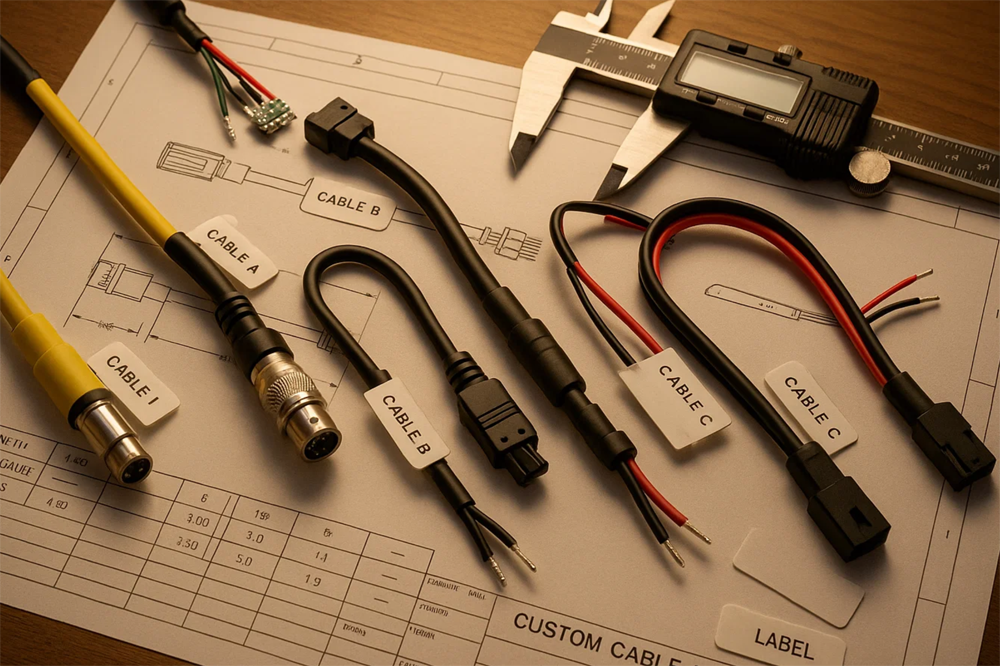

When it comes to custom wire and cable harness assemblies, quality is paramount – not just in materials, but in the assembly process itself. Smart engineers know to demand certain industry standards and certifications as a baseline for quality. These standards act as a checklist to ensure that every harness coming off the production line meets rigorous criteria for workmanship and reliability.

Below, we present 7 key assembly standards and quality benchmarks that savvy engineers look for, along with why each is important. Whether you’re evaluating a new harness manufacturer or setting up internal QA protocols, this checklist will help confirm that you’re adhering to best practices and delivering harnesses that won’t fail under pressure.

1. IPC/WHMA-A-620 Compliance – The Gold Standard

The IPC/WHMA-A-620 standard is the globally recognized benchmark for cable and wire harness assembly quality. It provides detailed criteria for every aspect of harness assembly: from how wires are stripped and crimped, to soldering requirements, to how lacing and tie wraps should be applied.

Smart engineers insist that their harnesses are built to IPC-A-620, often specifying the Class of workmanship required. For example, Class 3 is demanded for high-performance or safety-critical harnesses (like in medical devices or aerospace) where flawless execution is critical. Ensuring IPC-A-620 compliance means the manufacturer follows documented best practices – such as no nicks on conductor strands when stripping insulation, properly formed crimps with bellmouth and visible serrations, and correct routing and dressing of cables.

Many top manufacturers will have their staff IPC certified (CIS/CIT), indicating they have been trained to this standard. As a quality checklist item, you should confirm: Does the supplier build to IPC/WHMA-A-620, and can they provide evidence of training or certification? Meeting this standard significantly reduces the risk of assembly errors that could lead to failures.

2. ISO 9001 Quality Management System

While IPC-A-620 covers the product workmanship, ISO 9001 addresses the overall quality management of the organization building your harnesses. An ISO 9001:2015 certified manufacturer has a formal Quality Management System (QMS) in place – meaning they have standardized processes for production, inspection, handling of non-conformance, continuous improvement, and so on.

Smart engineers require ISO 9001 certification from their harness suppliers because it is evidence of a culture of quality and consistency. It’s not just about one harness being built right, but every harness being built the same way, with proper documentation and traceability. For instance, ISO 9001 ensures there are work instructions for each assembly, calibration of tools like crimpers and testers, and records of lot numbers for materials. This level of process control is vital for consistent quality.

A critical item for your checklist should be to verify if the manufacturer is ISO 9001 certified. If yes, you can have greater confidence that quality isn’t an afterthought but is baked into their operations.

3. UL and CSA Certification for Harnesses and Components

Safety certifications from bodies like UL (Underwriters Laboratories) or CSA (Canadian Standards Association) are another important standard smart engineers check for. These certifications indicate that the harness (or at least its components) meet safety requirements for things like flammability, insulation integrity, and safe operation.

For example, UL has a specific program for Wire Harnesses (UL Category ZKLU / ZPFW2) where an entire harness design can be UL certified. More commonly, engineers ensure that all components are UL-recognized or listed: wires with UL ratings (e.g. UL1015, UL1007), connectors that are UL94 V-0 flame rated, etc. If your product needs to be UL approved, using UL-certified harnesses and parts is a must – it avoids problems during the end-product certification.

On your checklist, you’d ask: Are all materials UL or CSA approved, and can the supplier provide a UL wiring harness label if needed? High-quality manufacturers often mention that they use UL-certified processes and will even stamp the UL mark on the harness tag if applicable.

4. WHMA/IPC Trusted Supplier Program or OEM Approvals

Beyond formal standards, many smart engineers look for less common but telling quality indicators. One such item is whether the supplier participates in any WHMA or IPC Trusted Supplier programs or has specific OEM customer approvals.

For instance, IPC has a Validation Services program where suppliers can get an IPC-A-620 Qualified Manufacturers Listing (QML) – effectively proving via audit that they consistently meet IPC-A-620. Similarly, some industries (like automotive) have their own supplier approval processes. If your project is in such an industry, those specific approvals become critical checklist items.

Even in general, a supplier that has taken steps to get an industry validation or award for quality demonstrates a commitment above the norm. While this is a “softer” criterion than a formal standard, it’s something sharp engineers inquire about: Has this supplier’s quality been vetted or recognized by any industry bodies or major customers? Positive answers here add confidence that you’re dealing with a top-tier provider.

5. Crimp Quality Standards

Crimping is the most common termination method in harnesses, and poor crimps are a frequent cause of failure. Thus, it deserves special attention. Beyond IPC-A-620, which covers crimp acceptability, smart engineers often specify adherence to specific crimp standards.

-

UL 486A/486B covers wire connections and lays out testing for pull-out force, electrical continuity, etc., for crimps.

-

IPC J-STD-001, which is generally for soldering electronics, also touches on crimped terminations and requires training for operators.

A key checklist item is to determine if the manufacturer follows recognized crimping standards and has a process for crimp validation. You might ask if they do routine pull testing on crimped joints as part of QC. World-class manufacturers will have crimp cross-section analysis equipment and calibrated crimp presses and will be able to show that each crimp meets both IPC and UL criteria.

6. 100% Electrical Testing and Inspection

A quality harness isn’t just built right; it’s tested to be right. Smart engineers require that every harness undergoes full electrical testing – typically meaning continuity testing for all connections and isolation testing for all irrelevant connections. HiPot testing is often included for high-voltage or densely packed harnesses to ensure insulation integrity.

The standard here is not a named spec but an expectation: 100% testing. Your checklist should explicitly include verification that every harness has been electrically tested (and HiPot if applicable). Also, does the supplier have an inspection protocol (incoming, in-process, final) per IPC-A-620 or equivalent? A reliable supplier will happily share their test reports or testing procedure. This ensures no harness with a mis-wire or short escapes into your products. Essentially, zero-defect delivery is the goal, and 100% testing is how you get there.

7. Environmental and Specialty Standards

Finally, smart engineers consider standards related to their industry or regulatory environment. RoHS compliance (and REACH) is now a baseline. Depending on your sector, other standards might be “must-haves” on the checklist:

-

IATF 16949: The automotive quality management standard. A certified manufacturer will have additional controls like PPAP (Production Part Approval Process).

-

AS9100: The analogous certification for aerospace or defense, indicating adherence to aerospace-grade quality systems.

-

MIL-specs: Various military specifications for wiring or testing.

-

ISO 13485: The quality system standard for medical devices.

The key takeaway is to identify any special compliance or industry-specific standard and include it in your requirements. These ensure not only that the harness is built right, but that it meets any external requirements for your product’s certification or market.

Conclusion

By using this 7-point quality checklist, engineers can vet potential harness manufacturers or set clear requirements for their current ones. It encapsulates the major standards – from IPC workmanship to quality systems to testing protocols. A harness supplier that meets all these criteria is likely world-class, and involving these standards in your discussions will signal to the supplier that you, as the client, have a strong quality focus. In turn, this tends to produce better outcomes, as the manufacturer will pay even closer attention. In short, demanding adherence to these standards means demanding excellence—and that’s exactly what you want when your product’s reliability is on the line.