Specialty Wire Harness

When Standard Doesn’t Work, Custom Starts Here

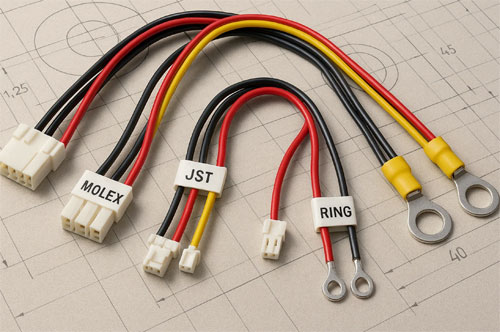

Not every wire harness fits into a catalog. Some require unusual layouts, mixed signal and power lines, or specialized materials to perform in demanding environments.

That’s where we come in. At Infinite Possibilities, we specialize in small-batch, custom-engineered specialty wire harnesses for customers who need more than just off-the-shelf parts. Whether you’re building a medical device, a test system, or a custom machine, we help turn your complex requirements into reliable, ready-to-use assemblies—with no minimums, no guesswork, and full support from start to finish.

From multi-branch signal lines to overmolded power connectors, we’ve built harnesses for projects where precision, durability, and clean integration are non-negotiable. With deep experience in problem-solving, we don’t just build what you send—we help you improve what you have. That means fewer errors, faster assembly, and fewer design headaches later on.

Get a Free Quote Now

Where These Harnesses Are Used

Built for systems that demand more than standard.

Medical & Diagnostic Equipment

Signal-safe, biocompatible, and sterilization-ready harnesses for imaging systems, surgical tools, and lab analyzers.

Laboratory & Test Instruments

Multi-branch, shielded harnesses built for high-precision sensors, modular test racks, and field diagnostics.

Robotics & Motion Control

Flexible and vibration-resistant harnesses for articulated arms, motion axes, and rotary systems.

High-Voltage or Mixed-Signal

Integrated power + signal lines with shielding and separation to ensure safe, stable transmission in compact systems.

Specialized Vehicles

Harnesses built to withstand vibration, temperature swings, and long-term mechanical stress in rail, off-road, or utility systems.

Custom Devices

Built-from-scratch harnesses for startups, R&D teams, and custom equipment makers launching new products.

What You Get – More Than Just a Harness

You don’t just get a product. You get fewer headaches, faster launches, and better outcomes.

Less Time Wasted

We understand drawings, ask the right questions, and make suggestions early—so you avoid delays and endless revisions.

Stable Quality

No unpleasant surprises. We match final production to the approved sample with 100% electrical and mechanical consistency.

Zero-Compromise Customization

No need to bend your design to fit off-the-shelf parts. We build exactly what your application needs.

Small-Volume, Engineering Friendly

We welcome early-stage projects, one-off prototypes, or tricky specs—no high MOQs, no frustration.

Frequently Asked Questions

Yes. You can send us a physical sample, rough sketch, or just your device layout. We’ll help translate that into a full production-ready harness.

Absolutely. We specialize in small-batch production, and support low-volume prototypes with no MOQ.

Yes. We often work with early-stage or in-development projects. Our team can provide layout suggestions, terminal selection help, and DFM feedback.

Yes. Just send us your test guide or pin definition, and we’ll align our production and QC accordingly.

We verify your drawings/samples in detail, do a fit & function check with every prototype, and offer revision support before mass production.Yes. We triple-check form, fit, and function—because we know you can’t afford failure in critical systems.