Control Wiring Harness

Custom Control Wiring Harness Solutions That Simplify Complexity

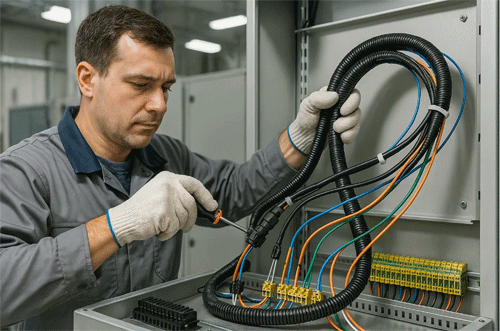

When your machines, panels, or automation systems rely on multiple control signals, clarity and consistency in wiring are critical. Messy or unreliable harnesses lead to downtime, troubleshooting headaches, and costly delays.

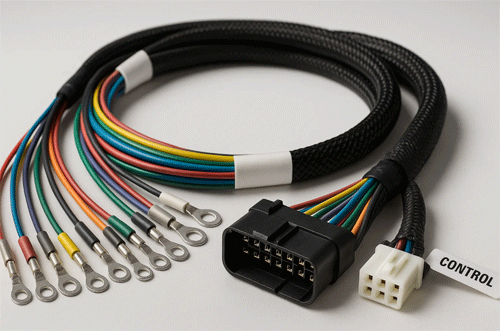

At Infinite Possibilities, we build custom control wire harnesses that simplify complex signal paths—with organized layouts, clear labeling, and robust electrical performance. Whether you’re handling relays, sensors, or PLCs, our solutions help reduce wiring confusion, avoid costly errors, and make your equipment easier to assemble, inspect, and maintain.

We support small to mid-sized orders with fast turnaround and full electrical testing—so you can focus on delivering reliable control systems, not managing wiring problems.

Get a Free Quote Now

Control Ready — Built for Precision & Reliability

Fast, stable, and reliable control harnesses that keep your system responsive and downtime low.

Real-Time Signal Delivery

Low-latency wiring ensures immediate response to critical control signals, minimizing operational lag and enhancing system responsiveness.

Shielded for Noise-Free Control

EMI/RFI shielding ensures that control signals are delivered accurately even in high-noise environments like engines or factories.

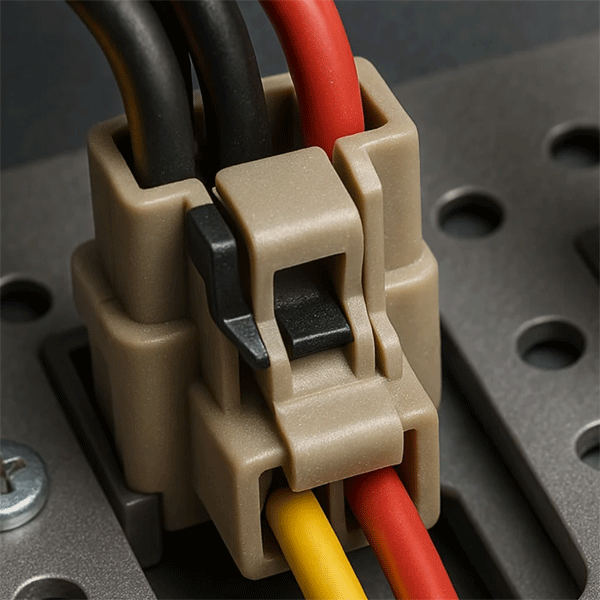

Secure Connector Locking

Firm locking connectors prevent disconnections under vibration or motion—reducing downtime and maintenance calls.

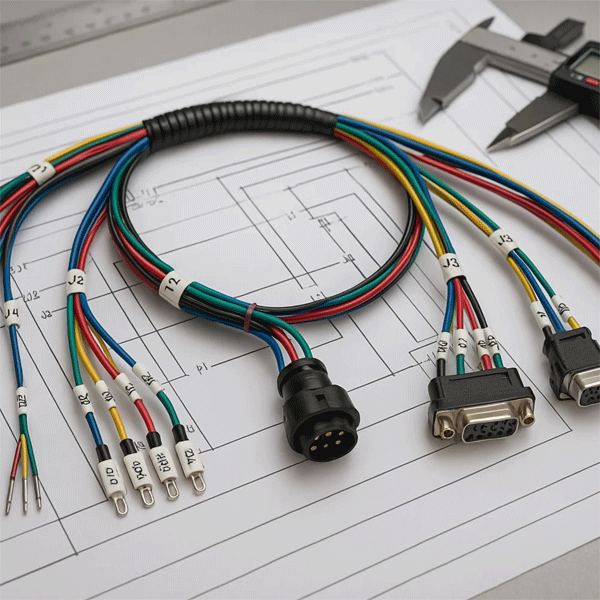

Labeling & Routing Optimization

Clear labeling and organized routing reduce setup and troubleshooting time, especially valuable for complex panels and machinery.

Built for Harsh Environments

We use heat-, oil-, and chemical-resistant materials for durability in automotive, industrial, and outdoor applications—ensuring your control never fails under pressure.

Typical Applications

Where Control Harnesses Matter

Smart HVAC Equipment

Used to manage temperature sensors, fans, dampers, and motorized valves—ensuring accurate climate control.

AGVs & Industrial Robots

Delivers stable signals for motion control, path correction, and safety circuits in mobile or robotic systems.

Medical Devices

Applied in imaging systems, diagnostic tools, and surgical equipment for precision control and system reliability.

Factory Automation Systems

Control harnesses connect PLCs, sensors, and actuators to enable seamless automation and feedback control in smart factories.

Construction & Agricultural

Control wiring handles functions like hydraulic actuation, lighting, and engine control in off-road vehicles.

Elevator & Lifting Systems

Supports signal routing for floor selection, emergency stops, and safety interlocks in building automation.

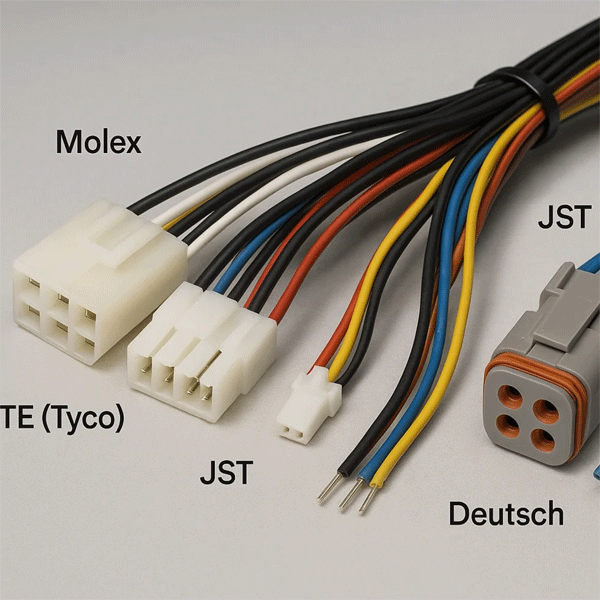

Connector Options

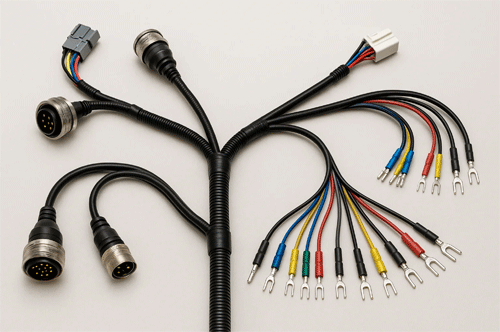

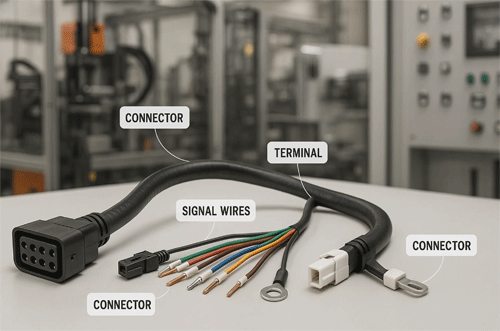

Our control wiring harnesses support a wide range of connector types to suit various control systems, modules, and installation requirements. Whether you need compact headers, ruggedized terminals, or custom plug assemblies, we deliver the right connection—on spec, every time.

Brand Compatibility

Supports Molex, TE, JST, Deutsch, Amphenol, and other industry-standard connectors.

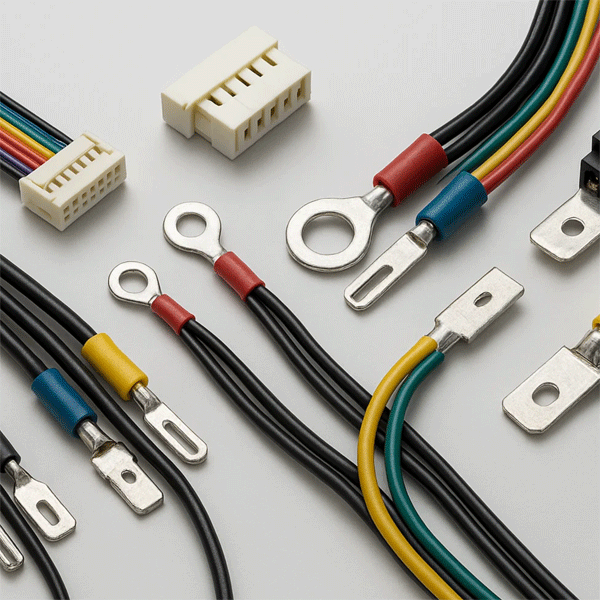

Connector Types

Available in IDC, crimp housings, ring terminals, blade terminals, screw terminals, and more.

Custom Pinouts

Fully customizable pin configurations, wire gauges, and breakout lengths according to your drawing.

Secure Locking

Locking tabs, latch mechanisms, and positive detents available to ensure vibration-proof connections.

Frequently Asked Questions

Control harnesses are designed for transmitting low-voltage signals between control devices like PLCs, relays, and sensors. Unlike power harnesses, they require clearer labeling, EMI shielding, and tighter routing to prevent signal confusion and improve reliability.

Yes. We can design and produce harnesses with multi-branch configurations, variable lengths, and custom routing to match your panel or equipment layout.

Absolutely. We offer heat-stamped, printed, or sleeve-style labels on each wire or terminal for quick and error-free connection.

Yes. Every control harness undergoes 100% electrical testing—including continuity, insulation resistance, and pull force checks—to ensure performance under real-world conditions.

Yes. We specialize in low to medium volume production. Whether you need 1 unit or 1,000, we support small runs, prototyping, and fast turnaround with no high MOQs.