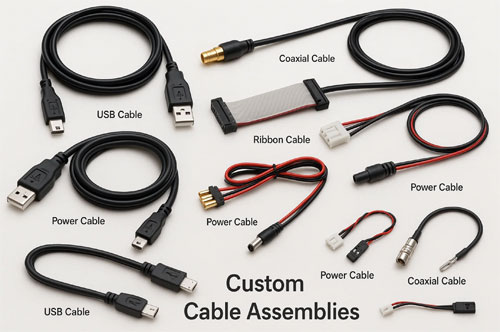

Custom Cable Assemblies

Why Custom Cable Assemblies?

The Fit Problem

Off‑the‑shelf cable assemblies rarely match the exact space envelopes, electrical specs, and compliance hurdles facing today’s products. As PCB densities climb, EMI margins tighten, and global safety codes evolve, a “good‑enough” stock cable can quickly turn into field failures, costly re‑work, or missed release dates. Forward‑thinking teams therefore start with custom cabling rather than retrofit it later.

Our Zero‑MOQ Solution

Infinite Possibilities bridges that gap with truly made‑to‑order cable assemblies—zero minimum order quantity, same‑week prototypes, and agile low‑to‑mid‑volume runs. Our engineers model conductor size, jacket compound, shielding, strain relief, and termination geometry around your CAD files. In‑house over‑molding, 100 % continuity testing, and UL/CE/RoHS documentation mean you move from concept to certified part without juggling multiple vendors.

The Payoff for You

The result is tighter tolerances, fewer production stops, and shorter time‑to‑market. You avoid the hidden costs of stock‑cable compromises—extra adapters, excess slack, EMI surprises—while gaining a supply partner who scales as your demand grows. In short: precision fit, predictable quality, and launch schedules that stay intact.

Get a Free Quote Now

What We Can Customize

From conductors to connectors—we build to fit, not to force.

Cable Type & Wire Gauge

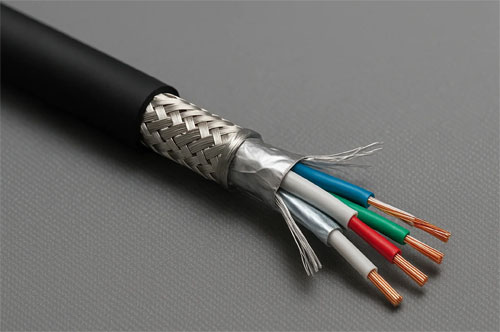

We support shielded, unshielded, flat, round, coaxial, twisted pair, ribbon, and hybrid cables in gauges from 10–30 AWG—tailored to your current, signal, and space requirements.

Custom Lengths & Layouts

All cables are cut, stripped, and routed to your exact dimensions—ready for fast plug-and-play assembly, with no trimming or on-site adjustment needed.

Connector Matching & Termination

We offer precise termination for JST, Molex, TE, Hirose, and custom connectors—supporting crimping, overmolding, soldering, and plug headers.

Labeling & Traceability

We provide heat-stamped labels, barcoding, and custom ID marks for accurate installation, batch tracking, and easy future maintenance.

Sleeving, Shielding & Overbraiding

We provide heat-stamped labels, barcoding, and custom ID marks for accurate installation, batch tracking, and easy future maintenance.

Typical Applications

From factory floors to smart devices—custom cables keep everything connected.

Industrial Automation Systems

Custom cables for motors, PLCs, sensors, and control panels—designed for vibration, heat, and tight routing within cabinets or machinery.

Test & Measurement Equipment

Reliable cable assemblies for lab instruments, analyzers, and test jigs—built for signal clarity and zero noise interference.

Medical Devices

Compact, flexible cables for TVs, home appliances, charging docks, and smart devices—engineered for easy installation and space efficiency.

Power & Energy Equipment

Heavy-duty cable assemblies for inverters, batteries, and solar systems—built to handle high current and outdoor exposure.

Networking & Telecom Modules

Cables for routers, control boxes, and signal distribution—supporting high-speed data, power, and RF transmission in one bundle.

Consumer Electronics & Appliances

Compact, flexible cables for TVs, home appliances, charging docks, and smart devices—engineered for easy installation and space efficiency.

What You Get

More than a cable. It’s an upgrade to your entire process.

Zero-Fit Issues, Zero Rework

Cables are built exactly to your specs, with labeled ends, correct routing, and proper strain relief—so everything fits right the first time.

Shorter Build Time, Smoother Projects

With plug-and-play readiness and easy identification, your installers save time and reduce mistakes—especially in tight production timelines.

No MOQ, Full Flexibility

From 2 units to 2,000—every order gets the same attention to detail. Perfect for early-stage development, pilot runs, or legacy replacements.

Fewer Headaches, Better Results

We help optimize materials, layouts, and interfaces—so you avoid electrical noise, mechanical failures, and last-minute surprises.

Frequently Asked Questions

Yes. Just share the mating connector type or layout, and we’ll ensure perfect fit—no guesswork, no misalignment.

Absolutely. We build hybrid assemblies combining high-current power cores and multi-pin signal wires within a single harness.

Yes. We offer overmolding options with TPU, PVC, or custom tooling to improve durability and prevent cable stress failures.

It depends on the cable type and function. For most signal and power assemblies, we support up to 10–15 meters with proper shielding.

Yes. We can source branded cables or components on request—including UL/CSA/CE certified materials to meet your compliance needs.