Flat Ribbon Cable Assemblies

Flat Ribbon Cable Assemblies – Compact, Organized, and Built for Precision

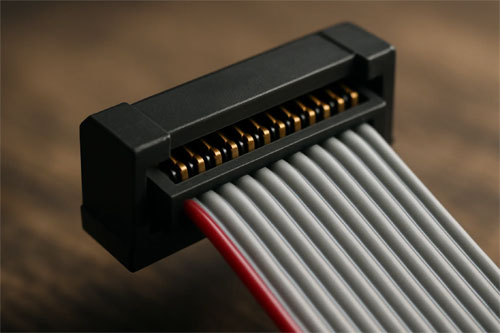

Flat ribbon cables are designed for tight spaces and clean layouts, making them ideal for internal connections in electronics, printers, automation equipment, and communication systems. Their parallel structure ensures precise signal routing, uniform impedance, and simple installation—especially in environments where traditional round cables are difficult to manage.

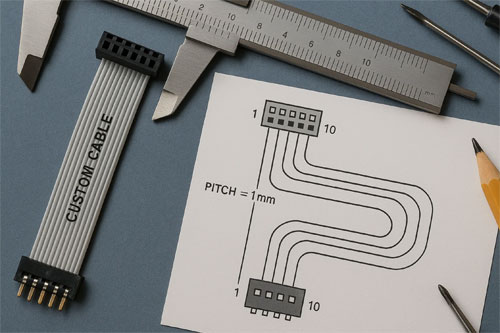

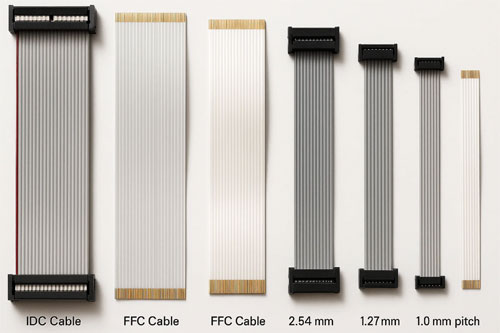

At Infinite Possibilities, we build fully customized ribbon cable assemblies based on your exact pinouts, pitch, and connector requirements. From IDC to FFC, we support a wide range of termination types, lengths, and configurations, helping you achieve the electrical and mechanical precision your system needs.

More importantly, we help you save time, reduce errors, and scale smoothly. Our cables arrive ready to install, clearly labeled, connector-matched, and fully tested. Whether you’re building 5 units or 500, we make sure you get hassle-free integration—on time, every time.

Get a Free Quote Now

Engineered for Clarity, Performance, and Seamless Fit

From precision pinouts to clean installs—built to meet your system’s demands.

Pre-Routed, Pre-Labeled

Cables arrive with precise segment lengths, terminal ID markers, and plug orientation—ready for plug-and-play. Save time, eliminate guesswork, and avoid costly field errors.

Precise Pitch & Impedance Control

Available in 0.5mm–2.54mm pitch, with balanced impedance for multi-line signal transmission—ideal for data, FFC, and LVDS. Protects your signals from cross-talk and distortion.

Connector Matching by Design

We terminate with IDC, DIP, ZIF, FFC, and more—straight, angled, or reverse-mounted—to match your port and board layout. No wire twisting, no reversed installs.

Multi-Branch Layouts for Modular Devices

Support for single-to-multi breakouts, parallel trunking, or board-to-board bridging—especially for complex enclosures. Power multiple boards from one harness, cleanly and clearly.

Shielded for High-Noise Environments

Add foil shielding and EMI wraps to protect sensitive signals from noise—ideal for medical, industrial, or telecom uses. Signal reliability, no matter the environment.

No MOQ, Full Customization

From a few test units to small-batch builds, we support low-volume, high-variation orders with full flexibility. Perfect for R&D, pilot runs, or evolving designs.

Typical Applications

Where Neatness Meets Necessity

Printers & Scanners

Ribbon cables simplify routing between control boards, print heads, and motors—ensuring reliable signal flow and compact design.

Medical Analyzers & Diagnostic Devices

Support compact internal wiring with minimal EMI—ideal for lab automation and patient-side instruments.

Control Panels & PLCs

Easily connect PCBs, sensors, or IO terminals in cabinets with organized, space-saving routing.

Consumer Electronics & Displays

Ideal for TVs, touchscreens, and smart devices where flat profile and reliable data transfer are essential.

Telecom & Networking

Support multi-line signal routing in routers, servers, and signal processors with clear identification and neat bundling.

Industrial Instruments & Robotics

Use in modular sensors, drive units, and embedded systems where flexible yet fixed-position routing is essential.

What You Get

Practical Benefits That Save Time, Space, and Stress

Ready-to-Use Cabling for Tight Spaces

Flat ribbon cables are pre-cut, terminated, and labeled—no twisting, trimming, or reconfiguring on-site. Your installers get it done faster with fewer errors.

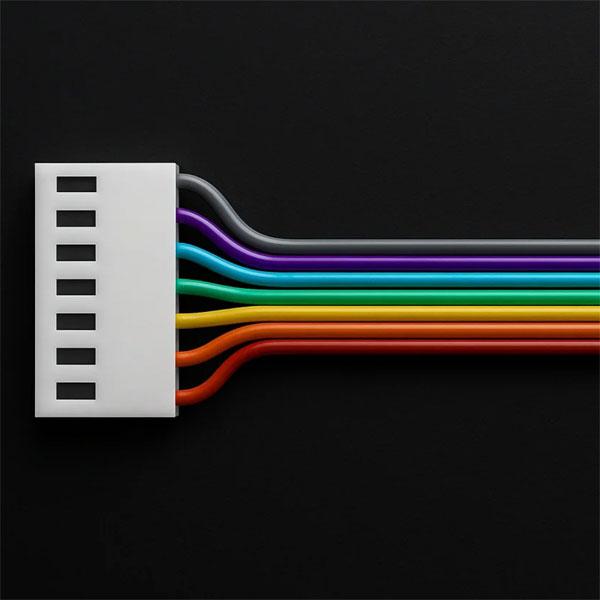

Clean Routing, Clean Results

With built-in alignment and color-coded layout, your device internals stay organized and inspection-friendly. Neater wiring equals better quality control.

Improved Signal Integrity by Design

Parallel layout, balanced impedance, and optional shielding reduce EMI and crosstalk—critical for data and sensor systems. Because clean signals mean fewer bugs.

Built for Fast and Design Freedom

Whether you're prototyping, A/B testing layouts, or revising your board design, we adapt quickly—without MOQ constraints. You can change, tweak, and grow—without starting over.

Frequently Asked Questions

We offer standard pitches from 0.5mm, 1.0mm, 1.27mm, 2.0mm, to 2.54mm, and can support mixed-pitch or customized requests based on your mating connector or layout.

Yes. We offer IDC, DIP, FFC, ZIF and other terminations, with full labeling, orientation control, and strain relief if needed.

Yes. We can add foil shielding, ground wires, or EMI wraps to enhance performance in high-noise environments.

Absolutely. We support split-type, mirrored, and multi-output layouts for modular or distributed systems.

Sample lead time is usually 5–7 working days, depending on complexity. Batch orders ship in 10–15 working days.