5 Hidden Factors That Drive Up Your Custom Cable Assembly Manufacturing Costs (And How to Avoid Them)

Table of Contents

Toggle5 Hidden Factors That Drive Up Your Custom Cable Assembly Manufacturing Costs

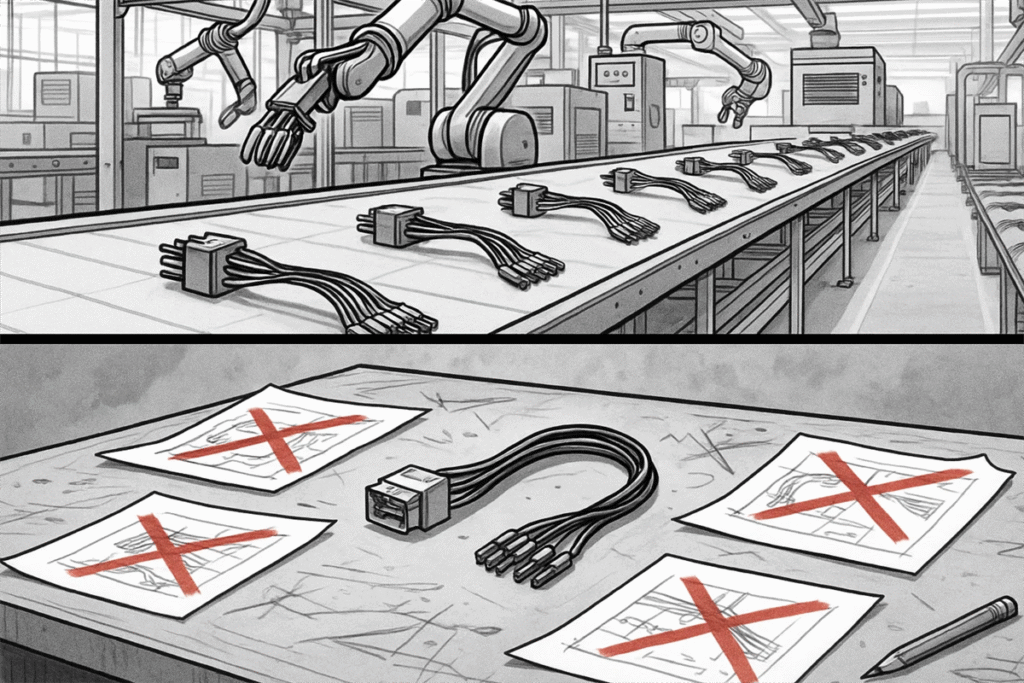

Getting a custom cable assembly designed and manufactured should be a straightforward process. You submit your design, get a quote, and receive a high-quality product that fits your application perfectly. But often, there’s a frustrating surprise: the quote comes back much higher than you anticipated. Why?

While obvious factors like material choices and order quantity play a role, the biggest cost drivers are often hidden within the details of your design and planning process. These are the subtle oversights and assumptions that can inflate your manufacturing costs without adding real value to your final product.

At Infinite Harness, we believe in transparent partnership. We want to empower you with the knowledge to not only build a better product but also to do it in the most cost-effective way possible. That’s why we’re pulling back the curtain on the five most common hidden factors that drive up custom cable assembly costs and, more importantly, how you can proactively avoid them.

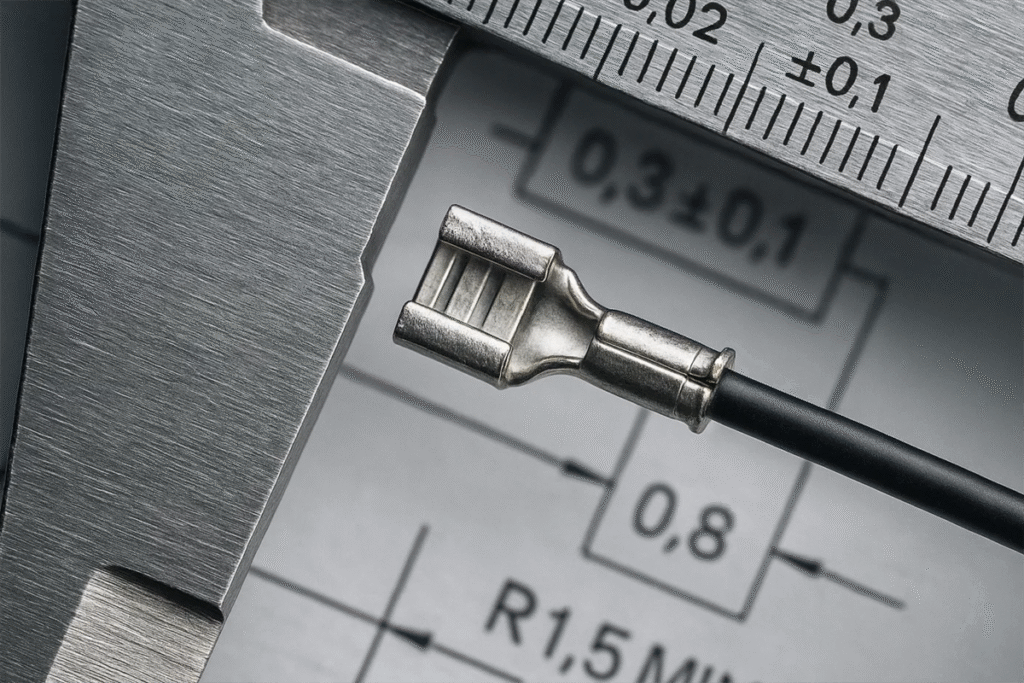

Factor 1: Over-Specifying Tolerances and Materials

In the world of engineering, precision is paramount. It’s tempting to specify the tightest possible tolerances and the most advanced materials to ensure maximum performance and durability. However, this “better safe than sorry” approach is one of the most significant hidden cost drivers.

The Cost Impact: Every specification on your drawing has a cost associated with it. An unnecessarily tight tolerance (e.g., a length tolerance of +/- 0.5mm when +/- 2mm would function identically) forces the manufacturer to slow down production, use more advanced measuring equipment, and increase quality control checks. This leads to higher labor costs and potentially higher scrap rates, as more assemblies may fall just outside the strict specification. Similarly, specifying a high-performance, military-grade wire insulation when a standard commercial-grade material would suffice can dramatically increase raw material costs without providing any functional benefit in your specific application.

How to Avoid It: The key is to practice “design for manufacturability” (DFM) by asking one simple question for every specification: “Is this absolutely necessary for the form, fit, and function of the assembly?”

- Consult Early: Engage with your manufacturing partner during the design phase. Share your application’s environmental and performance requirements. An experienced manufacturer like Infinite Harness can recommend standard, readily available materials and achievable tolerances that meet your needs at a fraction of the cost.

- Define Critical vs. Non-Critical: Clearly identify which dimensions are critical for mating or installation and which are not. Loosen tolerances on non-critical features to give the manufacturer more flexibility, which translates directly into cost savings for you.

Factor 2: Incomplete or Ambiguous Documentation

Your technical drawings (CAD files) and Bill of Materials (BOM) are the primary language you use to communicate your design to the manufacturer. When this language is unclear, incomplete, or ambiguous, it forces the manufacturer to make assumptions, which always involves pricing in risk.

The Cost Impact: If a drawing is missing information—such as wire colors, strip lengths, connector orientation, or required testing parameters—the manufacturer has two choices. They can either halt the quoting process to ask for clarification (delaying your project), or they can make a conservative assumption to cover a worst-case scenario. For example, if a BOM lists a generic part number without specifying an approved vendor, the manufacturer might quote the most expensive, readily available option to avoid potential compatibility issues, rather than a more cost-effective equivalent. This “risk premium” is built directly into your quote.

How to Avoid It: Treat your documentation as the single source of truth. Make it as detailed and clear as humanly possible.

- Complete BOM: Your Bill of Materials should include manufacturer part numbers, approved alternative parts (if any), and specific descriptions for each component.

- Annotated Drawings: Don’t rely on the 3D model alone. Your 2D drawings should include notes on everything from label content and placement to specific crimping standards and testing requirements.

- Create a “Documentation Checklist”: Before sending your RFQ (Request for Quote), run through a checklist: Is every component defined? Is every length specified? Are all testing procedures outlined? Is the BOM up to date?

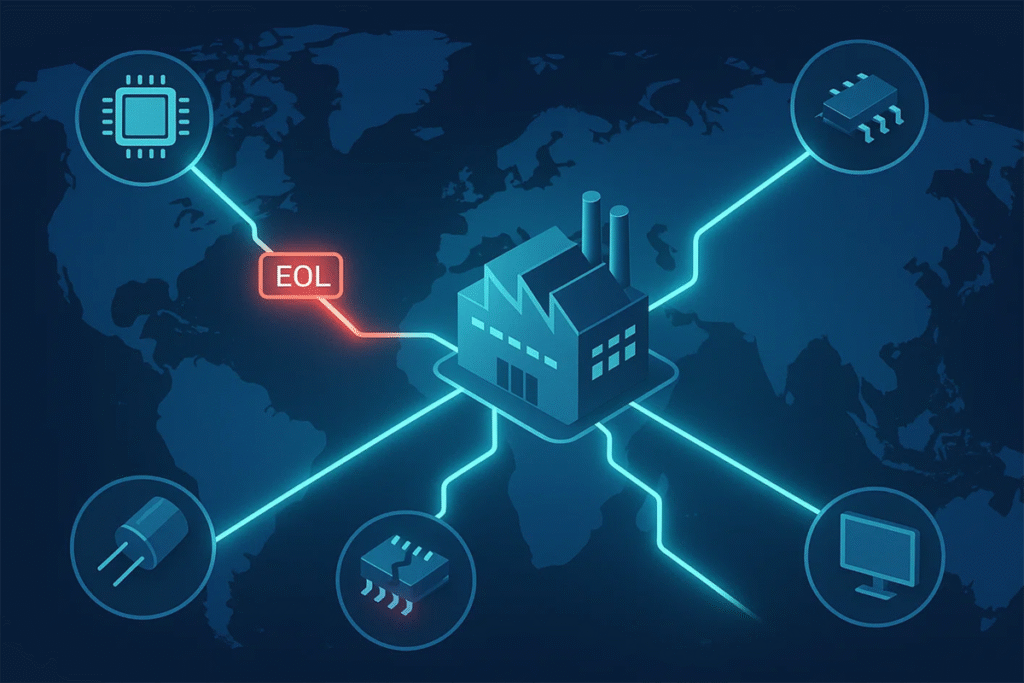

Factor 3: Ignoring Supply Chain Realities in Component Selection

The components you choose for your assembly have a life and a supply chain of their own. Specifying a connector or wire that is single-sourced, has a 52-week lead time, or is nearing its End-of-Life (EOL) can turn a straightforward project into a logistical nightmare.

The Cost Impact: Manufacturers price based on risk and effort. If they see a component on your BOM that is notoriously difficult to source, they will increase the price to cover the administrative overhead of tracking it down and the risk of production delays. If a part suddenly goes EOL mid-project, you are faced with expensive redesigns and requalification costs. Relying on single-sourced components also removes any pricing leverage, as that one supplier can dictate the cost.

How to Avoid It: Design with the supply chain in mind from day one.

- Specify Alternatives: Whenever possible, list pre-approved alternative components on your BOM. This gives your manufacturing partner the flexibility to choose the most available and cost-effective option without compromising your design.

- Check Lead Times & Part Status: Use online component databases or consult with your manufacturer to check the status and typical lead times of your chosen parts before finalizing the design. Avoid parts marked “Not Recommended for New Designs” (NRND) or “End-of-Life” (EOL).

- Leverage Your Partner’s Knowledge: An established cable assembly manufacturer has deep relationships with component distributors. They often have insight into which parts are reliable, readily available, and cost-effective. Use their expertise.

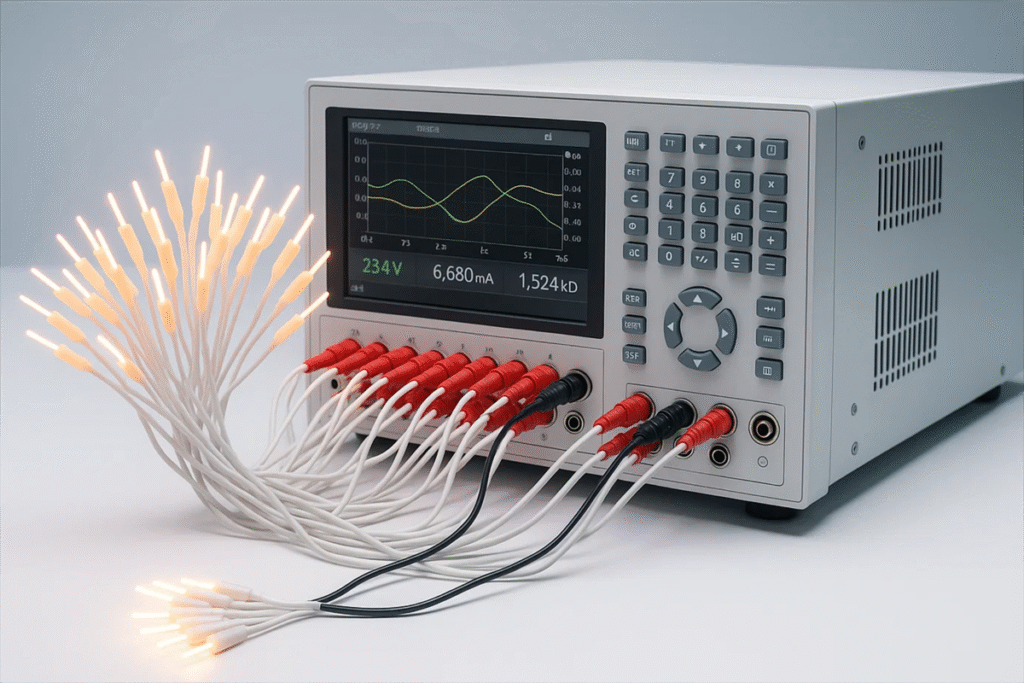

Factor 4: Unnecessary or Overly-Complex Testing Requirements

Testing is a critical step to ensure quality and reliability. However, not all assemblies require the same level of rigorous testing. Specifying 100% electrical testing on every single pin of a complex, non-critical assembly can be a major source of unnecessary cost.

The Cost Impact: Testing takes time, specialized equipment (like Cirris or DIT-MCO testers), and skilled labor. A simple continuity test might take seconds, but a full Hipot (high potential) or insulation resistance test can take several minutes per unit. When you multiply that time by hundreds or thousands of assemblies, the labor cost adds up significantly. Mandating 100% testing when a statistically valid batch testing protocol (like AQL – Acceptable Quality Limit) would suffice is a common way costs get inflated.

How to Avoid It: Match the testing requirements to the application’s risk profile.

- Define “Critical to Function”: Is the assembly for a life-support medical device or a non-critical internal connection in a consumer product? A life-support system absolutely requires 100% comprehensive testing. A simple internal data cable may only need a continuity check on a sample basis.

- Discuss Testing Options: Talk to your manufacturer about different testing levels. They can explain the cost-benefit trade-offs between simple continuity tests, resistance checks, full circuit testing, and Hipot testing, helping you select the most appropriate and cost-effective method.

Factor 5: Small Batch Sizes and Frequent Design Changes

The economics of manufacturing heavily favor consistency and volume. The setup process for a custom cable assembly—loading component reels, configuring crimping presses, setting up testing fixtures—is complex and takes the same amount of time whether you are building 10 units or 1,000.

The Cost Impact: When you order in very small batches, that high setup cost is amortized over fewer units, dramatically increasing your per-unit price. Furthermore, frequent last-minute changes to a design can be incredibly costly. It can force the manufacturer to halt production, scrap already-built sub-assemblies, and issue new work orders, all of which add administrative and material costs that are passed on to you.

How to Avoid It: Plan ahead and commit to a stable design.

- Forecast Your Demand: Whenever possible, try to forecast your needs for 6-12 months and place larger, scheduled orders (e.g., “ship 500 units per month for 6 months”) rather than small, ad-hoc monthly orders. This allows the manufacturer to plan their material purchasing and production, and they will pass those efficiency savings on to you.

- Freeze Your Design: Invest the time up front to finalize and validate your design before releasing it for mass production. While minor changes are sometimes unavoidable, treating a production release as the final version will save you significant money and time in the long run.

Conclusion: Your Greatest Cost-Saving Tool is Partnership

As we’ve seen, controlling the cost of your custom cable assemblies has less to do with haggling over the final price and more to do with smart, proactive decisions made early in the design process.

By avoiding over-specification, providing crystal-clear documentation, designing with the supply chain in mind, right-sizing your testing, and planning your production runs, you can eliminate the hidden factors that unnecessarily inflate costs.

The most powerful strategy of all is to stop thinking of your manufacturer as just a vendor and start treating them as an expert partner. An early conversation about your design can save you thousands of dollars and weeks of delays down the road.

Ready to build a high-performing cable assembly at the most optimal cost? Contact the experts at Infinite Harness today. Our team specializes in Design for Manufacturability and is ready to partner with you on your next project.